How to get the IEC 60086-4:2025 Test Report?

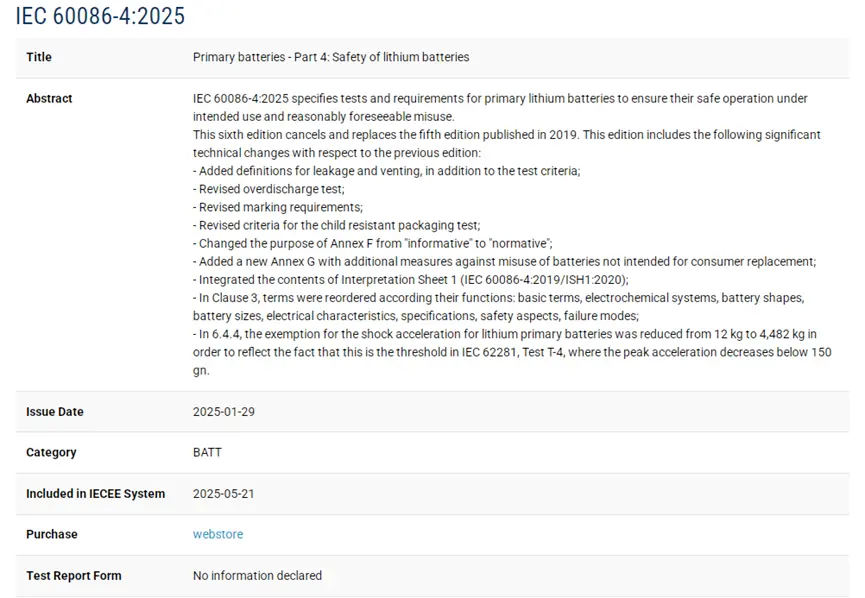

On January 29, 2025, the IECEEofficially released the iec 60086-4:2025safety standard for coin lithium batteries. On May 21, 2025, this standard was formally incorporated into the IECEE system.

IEC 60086-4:2025is an international safety standard issued by the International Electrotechnical Commission (IEC)for primary lithium batteries (non-rechargeable lithium batteries).

Key Changes in the New Version:

This version is a technical revision. CompaRED with the previous edition, it includes the following major technical updates:

a)Added definitions for leakage and venting based on testing standards

b)Revised the forced discharge test

c)Updated labeling requirements

d)Modified the child-resistant packaging test standards

e)Changed the purpose of Annex F from “Data” to “Standardization”

f)Added new Annex G, introducing extra measures to prevent accidental battery misuse by consumers

g)Integrated content from Interpretation Sheet 1 (IEC 60086-4:2019/ISH1:2020)

h)Reordered the terminology in Clause 3 by function: Basic Terms, ElectrocheMICal Systems, Battery Shapes, Sizes, Electrical Characteristics, Specifications, Safety, and Failure Modes

i)In Clause 6.4.4, the peak acceleration for lithium battery impact testing was reduced from 12,482 kg to 4,482 kg, aligning with IEC 6281 Test T-4 requirements (where peak acceleration drops below 150 gn)

I. Core Test Items

1. New Test M

Aimed specifically at spiral-structured batteries under over-discharge conditions, simULating scenarios where batteries are installed in reverse.

a. Setup:The test battery is connected in reverse with 3 identical, fully charged batteries (circuit resistance ≤ 0.1Ω)

b. Duration:24 hours or until battery returns to room temperature

c. Requirement:No explosion or fire

2. Basic Safety Tests

a. Environmental Adaptability

a. Altitude simulation (low pressure)

b. Temperature cycling (-40°C to 70°C)

c. Vibration (10–55Hz)

d. Mechanical shock (peak acceleration 150 gn)

b. Mechanical Safety

a. External short circuit (0.1Ω resistance, sustained for 7 days)

b. Crush test (13 kN pressure)

c. Free fall (1-meter height onto concrete surface)

c. Electrical Safety

a. Forced discharge (external short to 0V)

b. Abnormal charging (applied reverse voltage)

c. Over-discharge (voltage below 0V)

d. Child Protection

Child-resistant packaging test (must meet ASTM D3475 or Annex E of IEC 60086-4)

3. New and Revised Requirements

a. Leakage and Venting

Clear definitions and test standards outlined in Clause 310

b. Non-user-replaceable Batteries

New Annex G added, requiring extra precautions to prevent misuse (e.g., encapsulation design)

c. Updated Labeling

Labels must include over-discharge risk warnings and specific parameters (e.g., applicable models for Test M)

II. Process to Obtain the Test Report

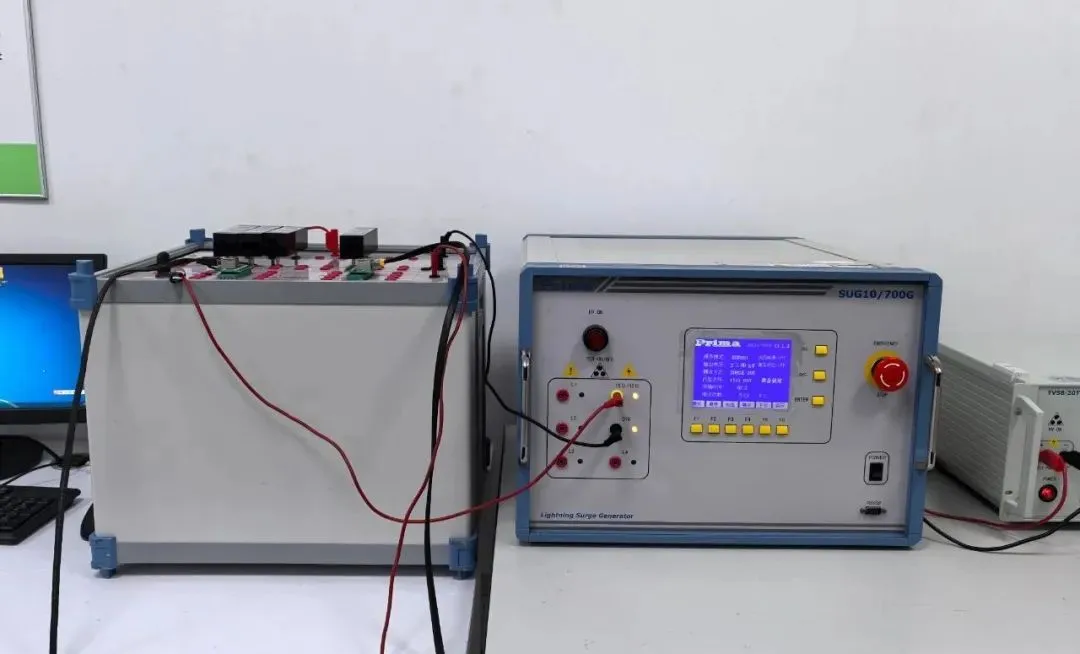

1. Choose a Testing Laboratory

Select a third-party lab accredited for IEC 60086-4:2025testing, such as JJR Labor similar. Confirm in advance whether the lab has updated its testing capabilities.

2. Submit Samples and Documents

a. Samples:Typically 10–20 batteries are required (actual number depends on the test items)

b. Documents:Battery specification sheet (including chemical composition, dimensions, electrical parameters), and application form (indicating model and applicable standards)

3. Testing Duration and Fees

a. Duration:Standard tests take about 2 weeks; Test M may require an additional 3–5 business days

b. Cost:Approx. USD 698–820 per test, depending on items and lab pricing

4. Test Report Content and Recognition

The report must include product details, test items, methods, results, and conclusions. It should bear the accreditation seal of CNAS, CMA, or ILAC-MRA.

This report is acceptable for audits by cross-border platforms like Amazonand TEMU, and can serve as evidence of export compliance.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the EN 61326-2-3 Standard?

What is the EN 61326-2-3 Standard?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Retest the Device if the 5G Module Already Has

Why Retest the Device if the 5G Module Already Has

Overview of IEC 62087 Test Standard

Overview of IEC 62087 Test Standard

CISPR 25 Test Standard Compliance Guide

CISPR 25 Test Standard Compliance Guide

IEC/UL/CSA 62368-1 Electrical Distance Testing

IEC/UL/CSA 62368-1 Electrical Distance Testing

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Leave us a message

24-hour online customer service at any time to respond, so that you worry!