What are the EMC Rectification plans for Medical Devices?

EMC (Electromagnetic Compatibility) rectification plans for medical devices need to be tailoRED to the type of equipment, usage environment, and specific issues. Typically, these plans include design optimization, shielding and filtering, grounding improvements, power management, and maintenance management. Below is a systematic rectification plan framework:

Equipment Assessment and Testing

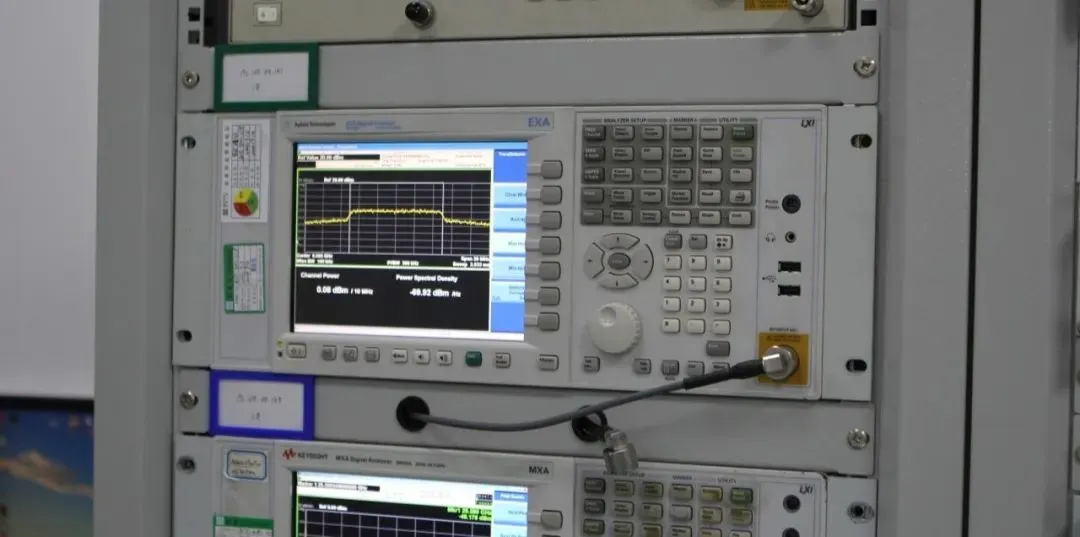

1. Comprehensive emc testing

- Radiation Testing: Evaluate the electromagnetic radiation levels of the device during normal operation to ensure they do not exceed limits.

- Immunity Testing: Verify whether the device can maintain normal operation when subjected to external electromagnetic interference.

- Conducted Emission Testing: Measure electromagnetic interference along the power supply lines and other conductive paths.

2. Problem Identification

- Analyze test resULts to identify interference sources (such as switch-mode power supplies, high-speed signal lines) and sensitive components (such as sensors, control circuits).

Design Optimization

1. Circuit Layout Improvements

- Reorganize the PCB layout to minimize crosstalk between high-speed and sensitive signal lines.

- Partition high-power and low-power components to reduce mutual interference.

2. Component Selection

- Choose low-noise, low-radiation electronic components, such as filter capacitors, inductors, etc.

- Optimize software design and incorporate anti-interference algorithms (such as digital filtering, error detection, and correction).

Shielding and Filtering

1. Electromagnetic Shielding

- Use metal casings or shields to enclose interference sources or sensitive components, reducing electromagnetic radiation leakage.

- Use shielded cables for connections, ensuring the shield is properly grounded.

2. Filtering

- Add filters (such as common-mode chokes, low-pass filters) at the power input and signal input/output ports to suppress high-frequency noise.

- Select appropriate filter parameters (such as inductance, rated current, common-mode rejection ratio).

Grounding and Power Management

1. Grounding Design

- Use multiple-point grounding or single-point grounding to ensure the grounding resistance meets requirements (usually ≤1Ω).

- Increase the area of the grounding body to improve the stability of the electromagnetic interference return path.

2. Power Management

- Use isolation transformers and power filters to suppress conducted interference on power lines.

- Use regulated power supplies to reduce the impact of voltage fluctuations on the device.

Data Transmission and Communication

1. Communication Interface Optimization

- Use shielded cables and differential signal transmission technologies to enhance the anti-interference ability of data transmission.

- Choose appropriate communication protocols (such as CAN bus, Ethernet) to ensure data reliability.

2. Electrostatic Protection

- Use anti-static materials at the device’s casing and interfaces to increase grounding area and rapidly discharge static electricity.

Maintenance and Management

1. Regular Testing

- Conduct regular emc tests on the device to promptly identify and resolve potential issues.

2. Component Replacement

- Replace aging components and connection wires in time to avoid EMC issues caused by performance degradation.

3. Environmental Control

- Keep the operating environment of the device clean and dry to reduce the impact of external interference sources (such as radio broadcasts, mobile communication base stations).

Training and Awareness Enhancement

1. Operator Training

- Increase healthcare personnel’s awareness of EMC issues and train them in proper usage and maintenance of medical devices.

2. Standard Operating Procedures

- Ensure compliance with operating procedures to minimize the impact of human factors on EMC performance.

Rectification Verification

1. Post-Rectification Testing

- After completing the rectification, re-test the EMC performance to verify whether the rectification effects meet the expectations.

2. Long-term Stability Testing

- Monitor the device in the actual operating environment over an extended period to ensure stable EMC performance.

Email:hello@jjrlab.com

Write your message here and send it to us

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Is SAA Certification Required for Lamps Sold to Au

Is SAA Certification Required for Lamps Sold to Au

Tablet PC RSS-247 Test Report

Tablet PC RSS-247 Test Report

Canada ISED Certification RSS-247 Standard Testing

Canada ISED Certification RSS-247 Standard Testing

What Are the Product Compliance for Amazon Austral

What Are the Product Compliance for Amazon Austral

Australia IoT Security Compliance

Australia IoT Security Compliance

V16 Warning Light EU EN 18031 Cybersecurity Certif

V16 Warning Light EU EN 18031 Cybersecurity Certif

Leave us a message

24-hour online customer service at any time to respond, so that you worry!