Children’s Products and Toy Testing

Children's products and toys are often consideRED a child’s closest companions. They play a crucial role in supporting intellectual development and ensuring physical and mental well-being. As such, they are indispensable in a child’s growth. However, if poorly designed or manufactured, these products can pose serious safety hazards and become a cause of accidental injury or health risks. To protect children, countries and regions across the globe have established strict regULatory frameworks for such products—and continue to refine and update these standards over time.

China is currently the world’s largest manufacturing hub for children’s products and toys, producing around 75% of the global supply. Due to frequent toy recall incidents in recent years, it is becoming increasingly important for manufacturers to stay informed about the latest safety regulations in different countries.

JJR Laboratory in China is an IEC 17025-accredited lab focused on helping businesses meet diverse international regulatory standards to ensure smooth product exports. The lab offers testing for a wide variety of children’s products, including:

- Baby feeding supplies

- Strollers, cribs, cradles, and high chairs

- Playpens, carriers, and ride-on toys

- Plush toys, plastic toys, and electronic toys

- Art and craft materials like crayons, watercolor pens, and modeling clay

JJR can conduct tests based on standards issued by multiple regions including Europe, the United States, China, Canada, Australia, New Zealand, and international bodies.

Key Testing Categories Include:

1. Physical and Mechanical Safety:

Standards such as EN 71-1, ASTM F963, GB 6675, ISO 8124-1, among others, are used to assess risks like sharp edges, small parts, or breakability.

2. Flammability Testing:

Separate methods are used for textile and non-textile materials, with applicable standards like EN 71-2, ASTM F963, ISO 8124-2.

3. Toxic Element Analysis (Heavy Metals):

Ensures limits for lead, cadmium, and other metals under standards like en 71-3, cpsia, REACH Annex XVII.

4. Purity of Fillings (Visual & CheMICal Methods):

Evaluates cleanliness and chemical safety of toy stuffing materials.

5. Phthalates Content:

Tested under various regulations such as REACH and CPSIA, ensuring non-toxicity of plasticizers used in toys.

6. Azo Dyes Testing:

Required under EU and Chinese textile standards to prevent use of carcinogenic dyes.

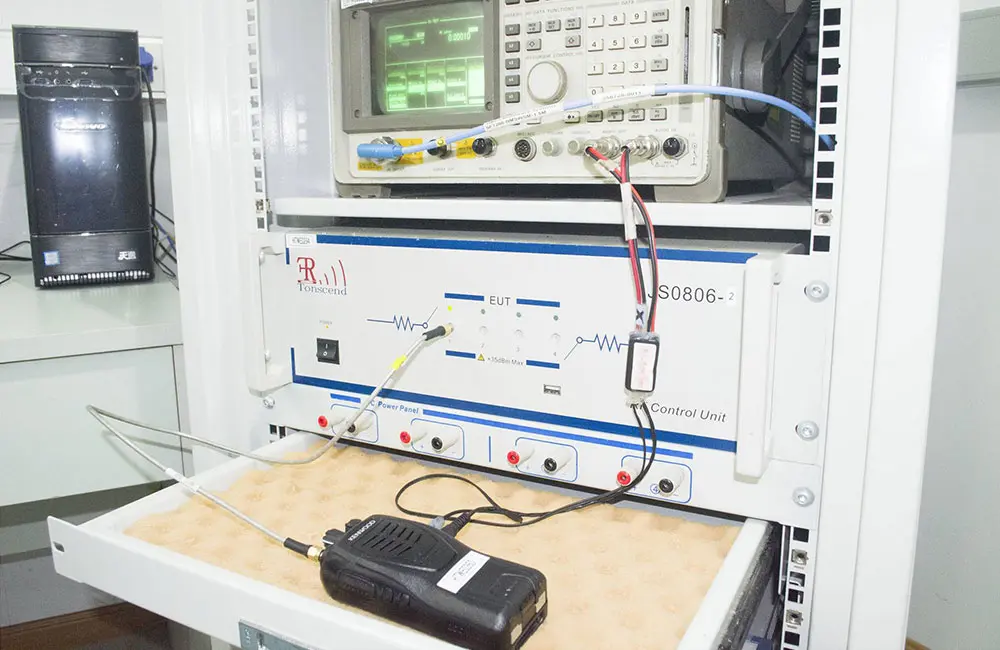

7. Electric Toy Testing:

Conducted in accordance with EN 62115, ASTM F963, and IEC 62115 for electrical safety in battery-operated toys.

8. Electromagnetic Compatibility (EMC):

Ensures toys with electrical components do not interfere with other devices. Tested under EU EMC directives, fcc part 15, and related national regulations.

9. Cosmetic Safety:

Applicable to toy cosmetics or kits, evaluated under EU Regulation No.1223/2009, U.S. FDA standards (21 CFR 700-740), and others.

Summary of Global Standards and Regulations:

- International: ISO 8124 (General Toy Safety Standards)

- China: GB 6675 (Toy Safety), GB 19865 (Electric Toys), GB 31701 (Children’s Textiles), GB 21027 (Student Supplies), GB 4806 (Food Contact Materials)

- European Union: Toy Safety Directive 2009/48/EC, EN 71, EN 62115, EMC Directive

- United States: CPSIA, ASTM F963, LHAMA & TRA (Art Material Safety)

- Canada: sor/2011-17 Toy Regulations

- Australia/New Zealand: AS/NZS ISO 8124

JJR Testing Services for Toys and Children's Products:

- Customized compliance solutions and expert consultation

- Regulatory and supply chain training programs

- Toy chemical safety assessments

- Comprehensive testing of products and components

Accreditations and International Recognition:

JJR Laboratory holds CNAS and CMA accreditations in China, is a member of Japan’s JAMP, and is officially recognized by the U.S. Consumer Product Safety Commission (CPSC) as an authorized third-party testing organization for the China region. JJR’s reports carry global credibility and are trusted by many leading companies both domestically and internationally.

Email:hello@jjrlab.com

Write your message here and send it to us

Japan IoT Security JC-STAR Certification

Japan IoT Security JC-STAR Certification

FCC SDoC Compliance Information Statement

FCC SDoC Compliance Information Statement

What Does FCC SDoC Certification Mean?

What Does FCC SDoC Certification Mean?

What is Bisphenol A (BPA) Testing?

What is Bisphenol A (BPA) Testing?

LED Display Export to the EU CE-EMC + RoHS Directi

LED Display Export to the EU CE-EMC + RoHS Directi

Children's Sleepwear Flammability 16 CFR 1615 / 16

Children's Sleepwear Flammability 16 CFR 1615 / 16

Speaker SAA & RCM Compliance AS/NZS 62368.1:20

Speaker SAA & RCM Compliance AS/NZS 62368.1:20

What is IEC 62052 for Electrical Energy Measuring

What is IEC 62052 for Electrical Energy Measuring

Leave us a message

24-hour online customer service at any time to respond, so that you worry!