CE Testing for Wooden Toys

What Are Wooden Toys?

Wooden toys are children's toys made primarily of natural wood (pine or beech) or composite wood materials such as MDF or plywood. Common forms include building blocks, puzzles, rocking horses, model cars and early education puzzles made of wooden material. Wooden toys are known to be environmentally-friendly and durable - two features valued by European and American parents alike.

Which Wooden Toys Require ce testing?

All wooden toys exported into the European Union require CE certification. ParticULar attention should be paid in these instances:

By Age Group:

Toys for ages 2 to 3.6 years focus more heavily on mechanical and physical safety, while toys for ages 3 and over 6 years often provide functional toys, such as scientific experiment kits.

Functional Designs for Toys:

1. Toys with Movable Parts (gears, joints)

2. Toys With Sound or Light Devices (which must comply with EN62115 standard)

3. Toys Coated in Paints or Varnishes May Present CheMICal Migration Issues

Core European Toy CE Testing Standards and Key Requirements

The EU Toy Safety Directive (2009/48/EC) serves as the foundation of toy CE testing requirements in Europe; specific testing of wooden toys follows EN71 series standards. There are three areas where specific attention needs to be directed:

EN71-1: Mechanical and Physical Properties

This test is of paramount importance, covering drop and impact resistance to ensure no breakages occur, small parts testing (requiring parts smaller than or equal to 31.75mm to remain attached without detachable), sharp edge elimination to protect from injury as well as detachable parts that don't detach easily (including small part testing). Sharp edges or points must also be eliminated to avoid injuries to employees and passengers, etc.

en71-2: Flammability

Materials must meet minimum burn rates of 20mm/s for softwoods and 20mm/s or lower for other materials, with stricter requirements in the case of softwoods. Flammable coatings like varnish are prohibited to mitigate fire risks.

EN71-3: Heavy Metal Migration (Chemical Safety)

Limits have been set on the migration of heavy metals from toy coatings and finishes: lead must fall below 90 mg/kg; cadmium 75 mg/kg; and arsenic 25 mg/kg respectively, to ensure chemical safety.

> Note:Toys that contain electronic components (for instance musical wooden xylophones) must comply with both EN62115 (electrical toy safety) and EMC (electromagnetic compatibility) requirements.

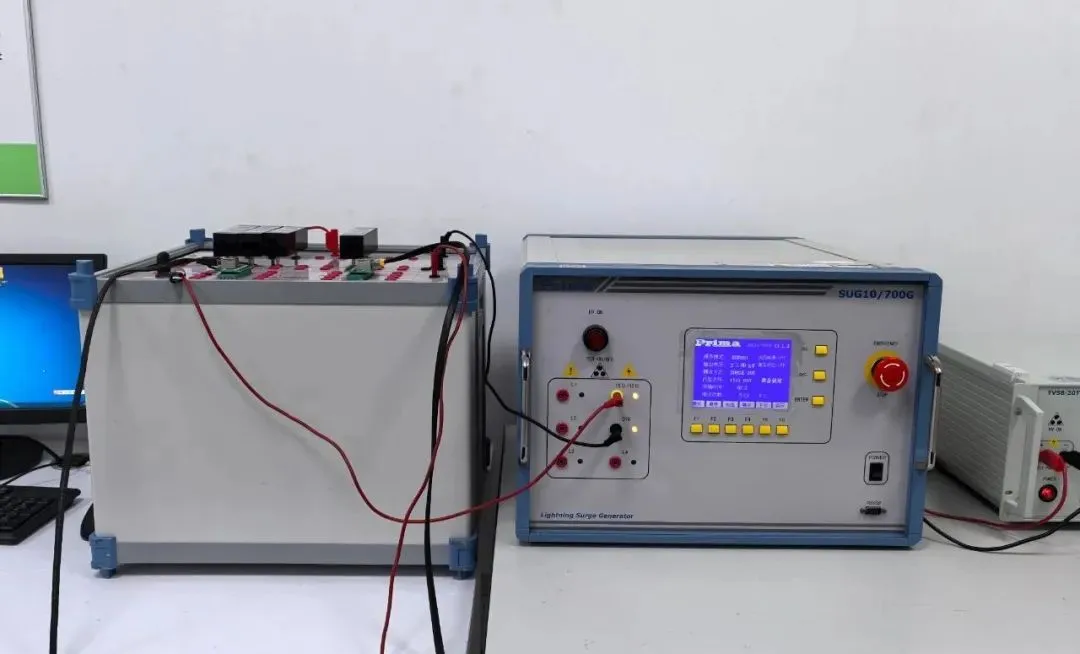

CE Testing Process Example: JJR Laboratory

Domestic manufacturers can complete CE testing at third-party labs recognized by the EU. As an example, JJR Laboratory — one of China's premier toy testing organizations — serves as an ideal example in this process. Here is its certification process:

1. Sample Submission Prep:

Submit 5-10 representative samples according to standards along with detailed product information such as materials, dimensions, target age group and design drawings.

2. Test Execution:

The lab conducts extensive mechanical/physical property and flammability/heavy metal testing according to en71 standards, offering original data reports as a result.

3. Technical Documentation Collection:

Companies compile a "Technical File", comprising design descriptions, material declarations, test reports and risk analyses as the "conformity evidence" requiRED by their directive. This file should also contain design sketches.

4. ce marking:

After successful testing and complete documentation, companies may apply the CE mark to products and packaging. The mark must be clearly visible and feature lab identification numbers.

> Tip:JJR Laboratory provides an all-in-one service that helps companies optimize their testing approach based on wooden toy characteristics, potentially shortening certification timelines by approximately 20%. This "one-stop" service also facilitates efficient sampling ratio adjustments according to wood properties.

Wooden toy CE testing is essential to entering the European market. The primary aim is preventing mechanical injury and chemical hazards. Working with professional labs such as JJR ensures efficient compliance while meeting EU safety standards without diminishing natural advantages associated with wooden toys.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the EN 61326-2-3 Standard?

What is the EN 61326-2-3 Standard?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Retest the Device if the 5G Module Already Has

Why Retest the Device if the 5G Module Already Has

Overview of IEC 62087 Test Standard

Overview of IEC 62087 Test Standard

CISPR 25 Test Standard Compliance Guide

CISPR 25 Test Standard Compliance Guide

IEC/UL/CSA 62368-1 Electrical Distance Testing

IEC/UL/CSA 62368-1 Electrical Distance Testing

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Leave us a message

24-hour online customer service at any time to respond, so that you worry!