ESD Electrostatic Discharge Test

Electrostatic Discharge (ESD) testing is one of the most fundamental and important types of tests in Electromagnetic Compatibility (EMC) assessments. It primarily evaluates the immunity of electrical and electronic equipment to electrostatic discharges.

According to the standard GB/T 17626.2-2018 and the international standard iec 61000-4-2:2008, ESD Testing is categorized into Contact Discharge and Air Discharge.

ESD Test Levels

Different test levels correspond to different test voltages:

- Level 1: Contact Discharge ±2kV, Air Discharge ±2kV

- Level 2: Contact Discharge ±4kV, Air Discharge ±4kV

- Level 3: Contact Discharge ±6kV, Air Discharge ±8kV

- Level 4: Contact Discharge ±8kV, Air Discharge ±15kV

Contact discharge directly applies discharge to the conductive metal surface of the equipment, while air discharge simULates electrostatic sparks via an air gap to non-conductive surfaces (such as plastic casings or slits).

The appropriate test level should be selected based on product type and industry standards. For example:

- Consumer electronics often use Level 2 or Level 3

- Industrial equipment typically uses Level 3

- Power equipment usually selects Level 4

- Railway transportation equipment commonly adopts Level 3

Validation of ESD Test Setup

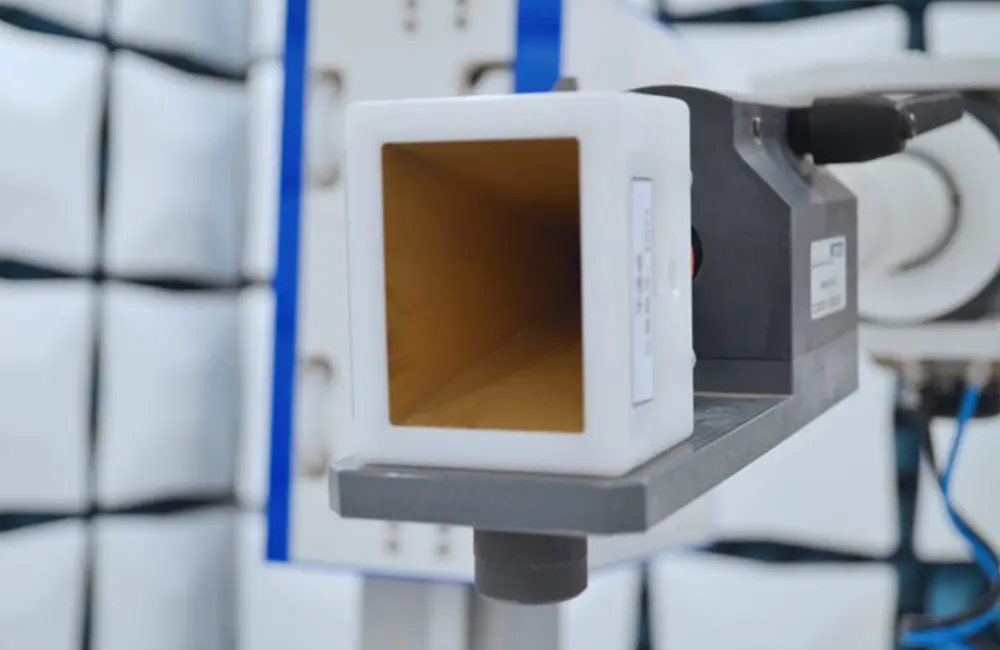

The purpose of validation is to ensure the ESD test setup is operational. The ESD test setup includes:

— ESD Generator

— Discharge circuit cable

— 470kΩ discharge resistor

— Ground reference plane

— All connections forming the discharge path

To validate a proper ESD test setup, one method is to observe small sparks during air discharge to the coupling plate at low voltage settings, and larger sparks at higher voltage settings. Before this, it is necessary to verify the connections and positioning of grounding straps.

Basic Principle:

Since the waveform parameters from the ESD generator typically remain stable (e.g., the rise time and duration of the waveform do not drift), the most likely failure modes include: the voltage not being deliveRED to the discharge electrode, or voltage control malfunction.

Damage, loosening, or absence of cables, resistors, or connecting wires in the discharge path can prevent proper discharge. It is recommended to validate the ESD setup before conducting tests.

Laboratory Environmental Conditions

The Equipment Under Test (EUT) should operate under expected climatic conditions. For air discharge testing, the environmental conditions should be within the following range:

1. Ambient temperature: 15°C to 35°C

2. Relative humidity: 30% to 60%

3. Atmospheric pressure: 86 kPa to 106 kPa

Performance Criteria for Test Results

Test results are classified into four performance levels based on functional behavior:

- Level A: Normal function during and after the test

- Level B: Temporary malfunction during the test, self-recoverable (no user intervention required)

- Level C: Malfunction requiring manual restart or adjustment (e.g., reset)

- Level D: Equipment damage or test failure

Email:hello@jjrlab.com

Write your message here and send it to us

EMC Item – Introduction to Radiated Emission Test

EMC Item – Introduction to Radiated Emission Test

IEC 62471 Photobiological Safety of Lamps and Lamp

IEC 62471 Photobiological Safety of Lamps and Lamp

New European Toy Standard EN 71-1:2026

New European Toy Standard EN 71-1:2026

EN71 Series Standards Compliance February 13, 2026

EN71 Series Standards Compliance February 13, 2026

European Toy Safety Standard EN 71-20:2025

European Toy Safety Standard EN 71-20:2025

EN 18031 Certification for Connected Devices on Am

EN 18031 Certification for Connected Devices on Am

Compliance Guide for Portable Batteries on Amazon

Compliance Guide for Portable Batteries on Amazon

2026 EU SVHC Candidate List (253 Substances)

2026 EU SVHC Candidate List (253 Substances)

Leave us a message

24-hour online customer service at any time to respond, so that you worry!