What is ANSI/UL 4200A-2023 (16 CFR 1263) Testing?

Overview of ul4200a Test Focus and Product Series Classification:

ul4200A is a recognized standard used to evaluate coin cells or consumer products containing coin cells. Compliance with UL4200A indicates that the coin cell or the coin cell–containing product REDuces the risk of accidental ingestion by children under normal use and certain foreseeable misuse conditions, in line with regulatory requirements.

UL4200A evaluation includes product construction, markings and user manual, and mechanical testing.

The purpose of all the requirements is to reduce the likelihood of children accessing and ingesting coin cells. The tests simulate conditions throughout the product’s lifecycle, including multiple battery replacements and exposure to normal use or foreseeable misuse (e.g., drops, crushes, impacts, plastic housing aging), while still meeting safety requirements.

UL4200A Structural Requirements:

1. User-replaceable coin cell products:Must comply with Sections 5.3–5.6 of the standard.

2. Non-user-replaceable coin cell products:Must comply with Section 5.7 of the standard.

UL4200A Testing (Required for both user-replaceable and non-user-replaceable coin cells):

1. Single Sample Test Sequence:

6.2.1A – Stress Relief Test:Heat the plastic enclosure to the highest temperature REACHed during testing +10°C, or at least 70°C, for a minimum of 7 hours.

6.2.1B – Battery Replacement Test:Open/close the battery cover and replace the coin cell 10 times. Refer to Table 20 of UL 60065 for screwdriver torque (minimum 0.4 Nm for metal screws with heads). This is especially critical for notebooks or tablets using small screws (e.g., M2 or smaller), which may strip after only two cycles but must complete all 10 cycles.

6.3.2 – Drop Test:3 drops for portable devices; 10 drops for handheld products.

6.3.3 – Impact Test:3 impacts at 2 joules.

6.3.4 – Crush Test:330 ± 5 N force over a 100 x 250 mm area for 10 seconds.

6.3.4A – Torque Test:If a child can grasp the battery cover with thumb + forefinger or teeth, apply 0.5 Nm torque.

6.3.4B – Tension Test:If a child can grasp the battery cover with thumb + forefinger or teeth, apply 72 N pulling force.

6.3.4C – Compression Test:If the battery cover is accessible to children but not impacted during drops, apply 136 N downward force.

6.3.5 – Compliance Test:After tests 6.3.2 to 6.3.4B, apply 50 ± 10 N force using an articulated finger for 10 seconds; the coin cell must remain inaccessible.

6.4 – Secureness Test:For non-replaceable coin cells fixed per 5.7B, and if the battery is accessible in 5.3/5.4 tests, apply a test hook force of 20 ± 2 N for 10 seconds.

UL4200A Manual and Marking Requirements:

1. Must include warning labels, pictograms, size, color, and font specifications.

2. Must include packing and product labeling.

3. Manual content must meet defined safety and communication standards.

Series Classification:

Multiple model numbers can be included in one report. Whether full or selective testing is done depends on the following factors:

1. Factors affecting mechanical integrity of the housing and test outcomes:

Product dimensions, housing thickness, weight, fastening methods, screw type/size, coin cell mounting method, alternate plastic housing sources.

2. Coin cell type:

Different types (e.g., CR2032 vs. CR2025) have varying thicknesses and may require structure review to determine if both types must be tested.

3. Lab vs. Client Testing Decisions:

If there’s a disagreement between the lab and the client on testing combinations, the client may specify the test configuration. The lab is responsible for conducting and validating tests for the specified sample.

Testing Services by JJR Laboratory (China):

JJR Laboratory offers ANSI/UL 4200a-2023 (16 cfr 1263) testing services for button cell products entering Amazon U.S. marketplace.

Report Fee:\$698 USD

Lead Time:7 days

Inquiries Welcome

Email:hello@jjrlab.com

Write your message here and send it to us

What is Protection Class EN 60529?

What is Protection Class EN 60529?

IP69 Certified Protection

IP69 Certified Protection

California Energy Commission Testing Lab

California Energy Commission Testing Lab

What Does the Canadian IC Mark Mean?

What Does the Canadian IC Mark Mean?

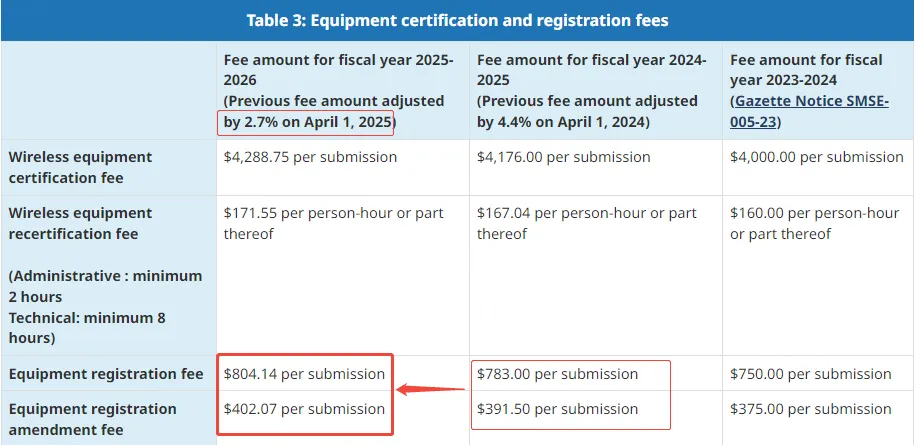

How Much is the Canada IC ID Certification cost?

How Much is the Canada IC ID Certification cost?

How Much is the Canada IC ID Certification Fee?

How Much is the Canada IC ID Certification Fee?

How Much is the UL 982 Test Report csost?

How Much is the UL 982 Test Report csost?

ISO/IEC 17025 Accredited Test Laboratory

ISO/IEC 17025 Accredited Test Laboratory

Leave us a message

24-hour online customer service at any time to respond, so that you worry!