What is the EN61326-2-3 Standard?

Today, let's take a look at the EN61326-2-3 standard—an important one in the field of electrical equipment.

What is the EN61326-2-3 Standard?

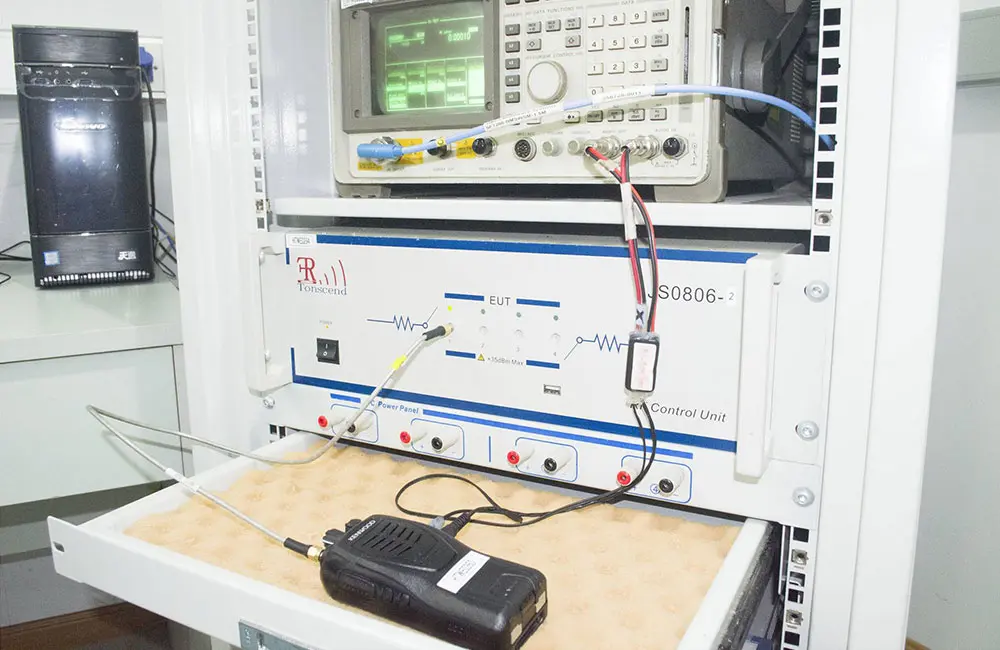

EN 61326-2-3 is a European EMC (Electromagnetic Compatibility) standard for electrical equipment used in measurement, control, and laboratory applications. It specifically applies to sensors with integrated or remote signal conditioning. The standard defines test configurations, operating conditions, and performance requirements to ensure stable operation in complex electromagnetic environments without interfering with other devices.

What products are coveRED by EN61326-2-3?

The EN 61326-2-3 standard applies to electrical equipment used in measurement, control, and laboratory environments—particULarly those with integrated or remote signal conditioning. Examples of applicable products include:

1. Transmitters: such as pressure, differential pressure, temperature, level, and flow transmitters. These typically convert physical quantities into electrical signals and transmit them to control systems or displays via signal conditioning.

2. Sensors and their systems: including temperature, humidity, pressure, displacement, speed, acceleration sensors, etc. If these sensors have integrated or remote signal conditioning functions that convert signals into usable electrical outputs, they fall under this standard.

3. Analytical instruments: such as spectrometers and chromatographs used in cheMICal analysis, or densitometers and viscometers for measuring physical properties. These usually include signal conditioning circuits to process signals from sensors for accurate results.

4. Data acquisition devices: such as data loggers or acquisition systems used to collect physical or electrical signals. These may include signal conditioning to adapt to various sensor inputs and convert data into digital form for storage and transmission.

5. Industrial control devices: including programmable logic controllers (PLCs), distributed control system (DCS) I/O modules, fieldbus devices, etc. These handle and condition signals from various sensors in automation systems.

6. Laboratory instruments: such as electronic balances, pH meters, conductivity meters, oscilloscopes, and signal generators. These are used for measurement and experimentation in labs and usually include signal processing features for accurate results.

What tests are required under EN61326-2-3?

EMC Emission Testing:

- Conducted emissions

- Radiated emissions

EMC Immunity Testing:

- Electrostatic discharge (ESD) immunity

- Radiated RF electromagnetic field immunity

- Electrical fast transient/burst immunity

- Surge immunity

- Conducted disturbance immunity

What should be noted when using this standard for CE certification?

1. Correct Standard Selection: Ensure your product is subject to EN61326-2-3. Choosing the wrong standard could invalidate your certification efforts.

2. Product Consistency: The tested product must match the production version. No discrepancies between test units and mass-produced units.

3. Certification Body: Choose a qualified and reputable certification body. Unreliable ones might lead to unrecognized results.

4. Standard Updates: Stay informed about revisions to EN61326-2-3. Manufacturers must ensure ongoing compliance with the latest version.

5. Performance Degradation Declaration: If the equipment is allowed to degrade in performance under interference, this must be clearly stated in the user manual.

6. Accredited Laboratories: Use third-party labs recognized by the EU to avoid invalid test results.

7. Documentation Integrity: Technical documentation should include complete records of design, testing, and risk analysis processes.

8. Final Product Testing: Tests must be conducted on production units, not prototypes.

That's all for our overview of the EN61326-2-3 standard. Hopefully, this has helped clarify things. Feel free to share this with others who might find it useful. And if you have any questions, don’t hesitate to REACH out!

Email:hello@jjrlab.com

Write your message here and send it to us

European Toy Safety Standard EN 71-20:2025

European Toy Safety Standard EN 71-20:2025

EN 18031 Certification for Connected Devices on Am

EN 18031 Certification for Connected Devices on Am

Compliance Guide for Portable Batteries on Amazon

Compliance Guide for Portable Batteries on Amazon

2026 EU SVHC Candidate List (253 Substances)

2026 EU SVHC Candidate List (253 Substances)

LFGB Certification Cost and Timeline Guide

LFGB Certification Cost and Timeline Guide

Bluetooth FCC Test Report

Bluetooth FCC Test Report

Is FCC Testing Required?

Is FCC Testing Required?

Where to Find FCC Test Reports

Where to Find FCC Test Reports

Leave us a message

24-hour online customer service at any time to respond, so that you worry!