ASTM F1912-19 Warning Label

Description of ASTM F1912 Standard

ASTM F1912 Standard Specification for Safety of Bean Bag Chairs

Introduction to ASTM F1912

ASTM F1912 is a safety standard specification for bean bag chairs established in the United States. The purpose of ASTM F1912 is to enhance the safety of bean bag chairs and their covers by addressing requirements for labeling and durability. Its primary goal is to REDuce the risks of suffocation and choking associated with these products.

By complying with ASTM F1912, manufacturers can improve the safety of bean bag chairs and significantly reduce the incidence of suffocation and choking hazards.

Scope of ASTM F1912

This standard applies to all bean bag chairs and their covers, regardless of whether they have zippers. It categorizes bean bag chairs into two types:

- Refillable Bean Bag Chairs:

Designed to be filled with polymeric or natural particULate materials. The zipper must be closed and permanently disabled. A force of at least 67 N is required to open the zipper directly.

- Non-Refillable Bean Bag Chairs:

Equipped with a permanent closure and not intended to be refilled. The zipper must be lockable and require a special tool, provided with the product instructions or at the time of purchase, to open or reopen. Without the special tool, a force of at least 67 N is needed to open the zipper directly.

Labeling Requirements of ASTM F1912

Bean bag chairs and covers must be equipped with permanently attached labels:

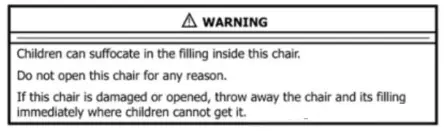

- Bean Bag Chairs with Zippers (Not Intended for Refill):

Must have a permanent warning label as shown below.

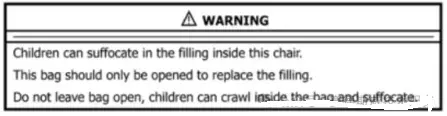

- Bean Bag Chairs and Covers with Zippers (Intended for Refill):

Must also include a permanent warning label.

- Instructions:

Detailed operating instructions for opening and reclosing the zipper must be included either on the warning label or on a separate permanent label.

Durability Test Requirements of ASTM F1912

Testing Conditions:

The test must be conducted at room temperature between 18°C and 27°C using a load composed of a cylindrical sandbag weighing 45.4 kg (100 lbs) with a bottom diameter of 16 inches. Place the bean bag chair on a horizontal concrete floor with the top center facing upward. Then proceed as follows:

- First Impact:

Drop the test load freely from a height of 8 inches above the top center of the bean bag chair.

- Subsequent Impacts:

After the first impact, reposition the test load 8 inches above the compressed top center of the bean bag chair and let it fall freely again.

- Repeated Impacts:

Repeat the subsequent impact procedure until a total of 300 impacts have been completed.

- Inspection:

Inspect the bean bag chair for any tears, openings, or leaks.

Evaluation Criteria for ASTM F1912 Durability Test

- After the durability test, closures and protruding parts must not fail.

- Seams must remain intact to ensure that no beads or filling material leak out.

- If an inner liner is present to hold beads, applying a force of 22 N or less with Probe A must not allow contact with the beads or the inner liner.

Email:hello@jjrlab.com

Write your message here and send it to us

What is IEC 62052 for Electrical Energy Measuring

What is IEC 62052 for Electrical Energy Measuring

Australia LoRa Band 915-928 MHz RCM Compliance

Australia LoRa Band 915-928 MHz RCM Compliance

What Are the Compliance Certifications for VHF Pro

What Are the Compliance Certifications for VHF Pro

Which Products Require WERCS Registration?

Which Products Require WERCS Registration?

Dustproof and Waterproof Ratings IP 54 / IP65 / IP

Dustproof and Waterproof Ratings IP 54 / IP65 / IP

SAR Standard Testing under the EU CE-RED Directive

SAR Standard Testing under the EU CE-RED Directive

Differences Between the Three EU Directives: LVD,

Differences Between the Three EU Directives: LVD,

How to get CE Marking Certification?

How to get CE Marking Certification?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!