Complete Guide to U.S. Toy Compliance Certification

In the context of globalized procurement, the toy and children's product industry faces stringent regulatory requirements. Non-compliant products can not only threaten children's health but also severely damage a company's reputation and business interests. This guide systematically outlines key compliance points for exporting toys to the United States, covering regulations, standards, testing requirements, and special category compliance. It provides operational guidance for brand owners, manufacturers, and importers.

Basic Compliance Framework for U.S. Toy Safety

1.1 Scope of Application

This scheme applies to conventional toys intended for children aged 12 and under, including but not limited to plush toys, plastic dolls, educational games, ride-on toys, and electronic toys.

1.2 Core Compliance Requirements

Safety Standard

① Standard: ASTM F963-23 "Standard Consumer Safety Specification for Toy Safety"

② Details: Covers physical and mechanical properties (small parts, sharp edges/points), flammability, chemical toxicity (heavy metals, phthalates), electrical safety, etc. Requires passing simulated abuse testing.

Chemical Control

a. Standard: CPSIA "Consumer Product Safety Improvement Act"

b. Requirements:

① Total lead content ≤ 90 ppm (in accessible parts)

② Phthalates (DEHP, DBP, and 6 others) ≤ 0.1%

③ Must provide third-party laboratory testing reports.

Labeling and Traceability

① Standard: CPSIA Tracking Label Requirements

② Details: Labels must be permanently affixed to the product and packaging, containing importer name, production location, production date, batch number, country of origin (e.g., "Made in China"; the use of easily removable stickers is prohibited).

Warning Labels

Requirement: For toys intended for children under 3 years, packaging and product must prominently state:

“CHOKING HAZARD - Small parts. Not for children under 3 years.”

Compliance certificate

Requirement: Each batch must be accompanied by a Children’s Product Certificate (CPC), listing test standards, laboratory information, product material list, signed by manufacturer or importer.

California Specific Requirements

① Standard: California Proposition 65 (CA Prop 65)

② Requirements: If the product contains lead, phthalates, or other chemicals, it must provide a warning label for "known to cause cancer or reproductive toxicity," and chemical content must comply with stricter limits (e.g., lead ≤ 100 ppm).

1.3 Exceptions

① Soft stuffed toys require additional legal URN number registration.

② Textile toys must comply with FTC "Textile Labeling Act" and CPSC care label requirements (such as washing instructions and material content).

Additional Compliance Requirements for Special Categories

(A) Electronic Toys (Including Remote-Controlled and Electric Toys)

1. Electromagnetic Compatibility (EMC) Requirements

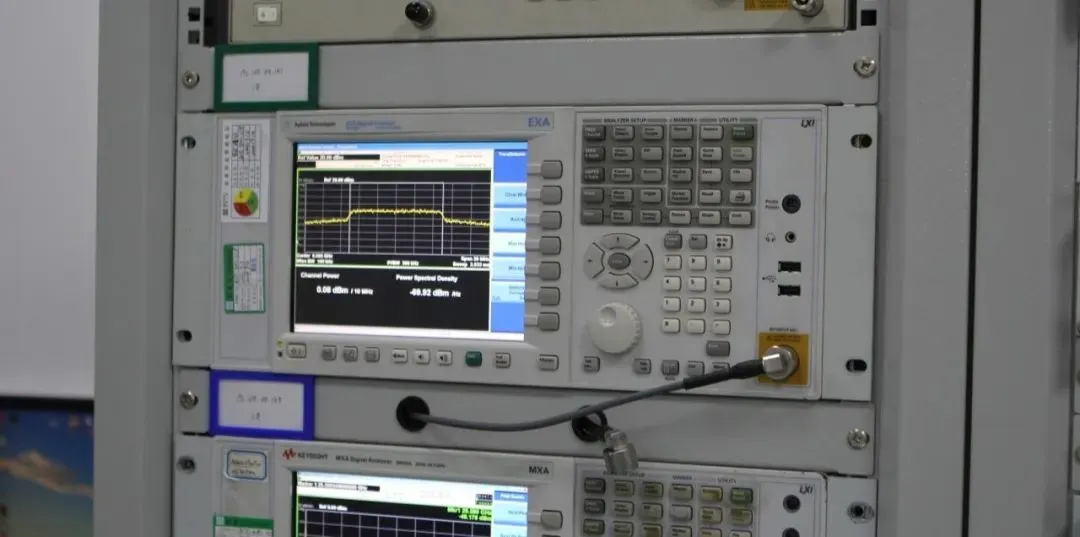

a. Regulatory Basis: fcc part 15 (applies to electronic devices operating at frequencies ≥ 9 kHz)

b. Compliance Process:

① Complete fcc certification testing (radiated emissions, conducted emissions, etc.); after passing, mark FCC label on product and packaging.

② Manufacturer/importer must sign a Supplier’s Declaration of Conformity (sdoc), including company information, product model, applicable standards (e.g., FCC Part 15 Subpart B), and signature date.

2. Electrical Safety Standards

a. Voluntary Certification:

① UL certification: Must comply with UL 696 (electric toys), UL 498 (plugs and sockets), etc. Amazon and major retailers generally require ul test reports.

② etl certification: Equivalent to UL, issued by Intertek, which can accelerate North American market entry.

b. Liability Warning: Products that fail electrical safety tests and cause accidents may result in importers bearing full legal responsibility. It is recommended to complete relevant certification mandatorily.

(B) Wooden Toys

1. Plant and Animal Quarantine Requirements

a. Regulatory Authority: USDA APHIS (Animal and Plant Health Inspection Service)

b. Compliance Points:

① Manufacturing enterprises must be approved by APHIS to ensure production environment meets sanitation, pest control, and traceability requirements.

② Wood must be heat-treated (core temperature ≥ 56°C for at least 30 minutes) or fumigated, with treatment records kept.

③ Toys containing composite wood panels (such as plywood, MDF) must comply with EPA/CARB certification, with formaldehyde emissions ≤ 0.09 ppm.

2. Physical Safety Testing

Extra focus on burrs, wood splinters, and other mechanical hazards. Toys must pass sharp points and edges tests specified in ASTM F963-23. Lead content in surface coatings is recommended to be tested separately.

Compliance Execution Recommendations

3.1 Supply Chain Control

① Raw Material Procurement: Require suppliers to provide Material Safety Data Sheets (MSDS) clearly stating chemical composition.

② Production Process: Establish batch traceability systems to ensure tracking labels can be traced back to raw material batches and production shifts.

3.2 Testing and Certification Planning

① Regular Toys: Complete full ASTM F963 testing, CPSIA chemical testing, and small parts swallowing tests before mass production.

② Electronic Toys: Simultaneously pursue FCC certification and UL/ETL electrical safety testing, allowing 3-4 months for certification.

③ Wooden Toys: Apply early for USDA APHIS factory certification; wood treatments must be completed at qualified facilities.

3.3 Document and Archive Management

① Retention Period: CPC certificates, test reports, and traceability records must be kept for at least 10 years to comply with CPSC audits.

② Language Requirements: All compliance documents must be in English. For multi-language labels, ensure the English version is the baseline.

3.4 Market Access Review

① Amazon Platform: CPC certificates and UL reports (if applicable) must be submitted in advance to the seller center for review; products failing review will be delisted.

② Physical Retailers: Large chain supermarkets (such as Walmart and Target) usually require suppliers to pass social responsibility audits (e.g., Sedex, BSCI). Early planning is advised.

Risk Warnings

4.1 Recall Consequences

Non-compliant products may face mandatory recalls by CPSC. Companies must bear costs of returns, destruction, and consumer compensation. Additionally, they risk being placed on the "Bad Importer List."

4.2 Regulatory Updates

U.S. toy safety standards are frequently updated (e.g., ASTM F963 is revised every two years). It is recommended to subscribe to CPSC official notifications or engage third-party compliance agencies for real-time regulatory monitoring.

Email:hello@jjrlab.com

Write your message here and send it to us

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Is SAA Certification Required for Lamps Sold to Au

Is SAA Certification Required for Lamps Sold to Au

Tablet PC RSS-247 Test Report

Tablet PC RSS-247 Test Report

Canada ISED Certification RSS-247 Standard Testing

Canada ISED Certification RSS-247 Standard Testing

What Are the Product Compliance for Amazon Austral

What Are the Product Compliance for Amazon Austral

Australia IoT Security Compliance

Australia IoT Security Compliance

V16 Warning Light EU EN 18031 Cybersecurity Certif

V16 Warning Light EU EN 18031 Cybersecurity Certif

Leave us a message

24-hour online customer service at any time to respond, so that you worry!