CPSIA Compliance Test

This article will elaborate on the cpsia (Consumer Product Safety Improvement Act) testing standards and how to successfULly pass the cpsia test. First, it introduces the background and importance of CPSIA; then, it explores in detail how to ensure products comply with CPSIA requirements and pass the test smoothly from four aspects: product material selection, product design and production, product testing and certification, and product documentation and labeling.

1. Background and Importance of CPSIA

CPSIA is a consumer product improvement act in the United States targeting children's products, aimed at protecting children from dangerous and harmful products. cpsia testing standards are an important regulatory requirement for companies that produce and sell children's products. Products that fail to pass CPSIA testing cannot be marketed, leading to significant financial losses and reputational risks for companies.

To successfully pass CPSIA testing, companies need to fully understand CPSIA requirements and ensure compliance in product material selection, design and production, and testing and certification.

2. Product Material Selection

Selecting the right product materials is the first step in ensuring compliance with CPSIA requirements. Companies should choose materials that comply with CPSIA restrictions, such as those free of prohibited toxic substances and heavy metals like lead and cadmium. Additionally, materials should pass CPSIA-specified tests to ensure product safety.

Establishing a good partnership with suppliers is also key. Companies need to regularly audit suppliers' quality systems to ensure that the provided materials meet CPSIA requirements. Signing compliance declarations with suppliers can help guarantee product safety and compliance.

3. Product Design and Production

Product design and production are crucial compliance stages. Design teams should closely follow CPSIA requirements, ensuring compliance in terms of product structure, dimensions, usability, and safety measures. For example, toy designs should prevent small parts that could be swallowed or cause choking hazards, and flame-resistant materials should be used.

The production process must also be strictly controlled to ensure each batch of products meets CPSIA standards. A complete production record and quality control system should be established to facilitate material tracking and product traceability.

4. Product Testing and Certification

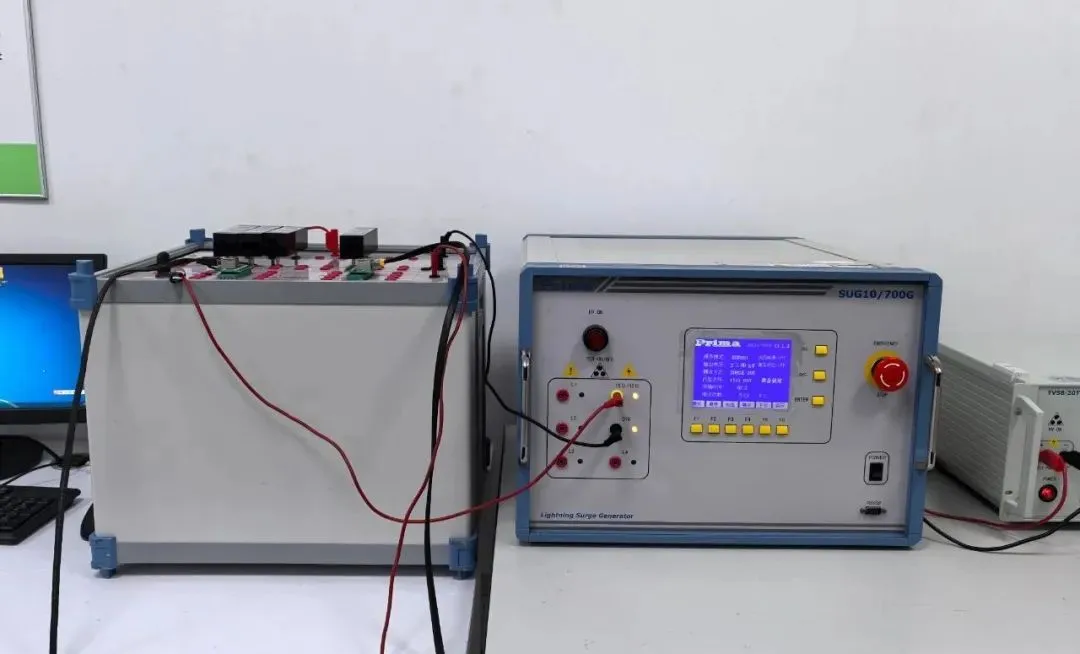

Product testing and certification are essential steps in ensuring compliance with CPSIA requirements. Companies should choose accREDited laboratories that meet CPSIA standards to conduct tests, including harmful substance analysis, physical performance testing, and electronic performance evaluation.

After passing the tests, companies should apply for cpsia certification and label the products with the CPSIA certification mark. Additionally, they should maintain relevant test records and certification documents for inspection and regulatory review.

Through a detailed explanation of CPSIA testing standards, it is evident that compliance with CPSIA requirements is essential for product conformity. To successfully pass CPSIA testing, companies must prepare and operate effectively in material selection, design and production, testing and certification, and documentation and labeling. Establishing strong partnerships with suppliers and accredited laboratories is also crucial.

Only by ensuring compliance with CPSIA requirements can companies obtain CPSIA certification, guarantee product compliance, and enhance their competitiveness and market credibility. Therefore, for companies that manufacture and sell children's products, fully understanding and adhering to CPSIA testing standards is of utmost importance.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the EN 61326-2-3 Standard?

What is the EN 61326-2-3 Standard?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Retest the Device if the 5G Module Already Has

Why Retest the Device if the 5G Module Already Has

Overview of IEC 62087 Test Standard

Overview of IEC 62087 Test Standard

CISPR 25 Test Standard Compliance Guide

CISPR 25 Test Standard Compliance Guide

IEC/UL/CSA 62368-1 Electrical Distance Testing

IEC/UL/CSA 62368-1 Electrical Distance Testing

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Leave us a message

24-hour online customer service at any time to respond, so that you worry!