IECEE Releases Safety Testing Standard for Button Batteries

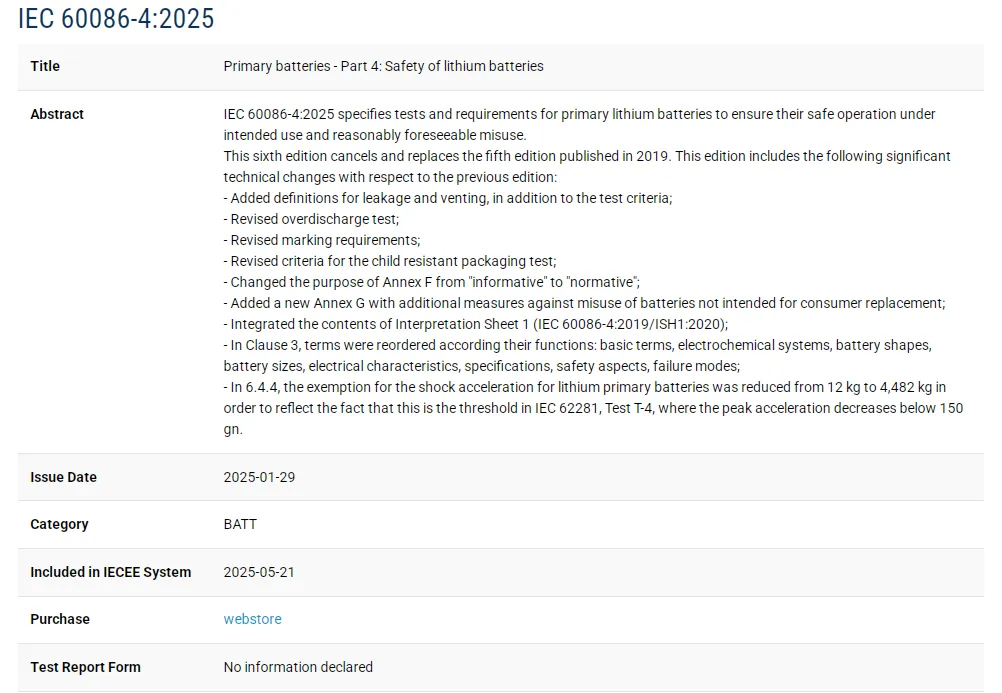

On January 29, 2025, the IECEE officially released the safety testing standard iec 60086-4:2025for button-type lithium batteries. On May 21, 2025, the IECEE formally incorporated this standard into its system.

This standard specifies testing methods and safety requirements for primary lithium batteries, aiming to ensure safe operation under both intended use and reasonably foreseeable misuse. Details are as follows.

Scope of Application

This standard applies to all non-rechargeable primary lithium batteries, including those used in remote controls, medical devices, military equipment, and other related fields.

Major Technical Changes

1. Added definitions for leakage and venting to the testing standard.

2. Revised the over-discharge test procedure.

3. Updated requirements for battery markings.

4. Revised child-resistant packaging test standards.

5. Changed Annex F from “informative” to “normative.”

6. Added a new Annex G introducing additional measures to prevent unintentional battery misuse during consumer replacement.

7. Integrated the explanatory content from Table 1 (IEC 60086-4:19 19/ISH1:2020).

8. In Clause 3, reordeRED terminology by function: basic terms, electrocheMICal systems, battery shapes, battery dimensions, electrical characteristics, specifications, safety aspects, and failure modes.

9. In Section 6.4.4, reduced the impact acceleration exemption for primary lithium batteries from 12 kg to 4.482 kg, reflecting the IEC 62281 T-4 test threshold, where peak acceleration is reduced to below 150 gn.

Testing Requirements

Batteries must undergo a fULl range of safety tests, including:

1. Short-circuit tests

2. Over-discharge tests

3. Drop tests

4. Overheating tests

5. Compression tests

6. Impact tests

7. Child-resistant packaging tests

These procedures ensure the battery meets safety requirements during normal and foreseeable use.

Safety Requirements

1. Labeling Requirements:

All batteries must carry clear and prominent safety labels, including warnings, usage precautions, and safety markings, to ensure correct use and prevent accidents.

2. Fault Handling:

If a battery fails, the power supply must be immediately disconnected to prevent further damage. Additional measures must be taken to ensure user safety.

Recommendation from China’s JJR Laboratory

Enterprises are strongly encouraged to:

3. Update product markings and labels without delay.

4. Conduct all necessary safety tests to verify compliance with the new standard.

5. Ensure products meet both the safety performance and manufacturing process requirements outlined in the standard.

These steps will help products enter and compete successfully in overseas markets.

Email:hello@jjrlab.com

Write your message here and send it to us

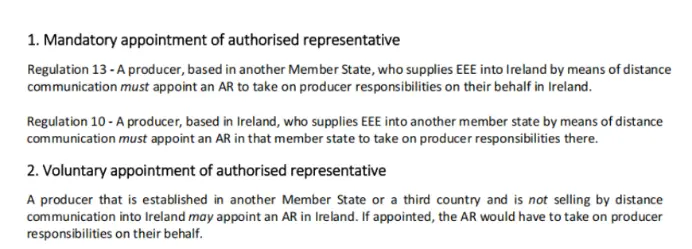

Irish Battery Act Requires an Authorised Represent

Irish Battery Act Requires an Authorised Represent

Swedish Battery Act Requires an Authorised Represe

Swedish Battery Act Requires an Authorised Represe

Amazon TIC Provider

Amazon TIC Provider

Amazon Battery and Charger Requirements

Amazon Battery and Charger Requirements

Amazon Japan METI A Domestic Administrator Service

Amazon Japan METI A Domestic Administrator Service

What is "Amazon Japan PSE: A Domestic Adminis

What is "Amazon Japan PSE: A Domestic Adminis

What Does "ASTM F963-17 Certified" Mean?

What Does "ASTM F963-17 Certified" Mean?

ASTM F963 Board Games Compliance Testing

ASTM F963 Board Games Compliance Testing

Leave us a message

24-hour online customer service at any time to respond, so that you worry!