In-depth Interpretation of SAA Certification Q&A

In the process of exploring the Australian market, saa certification is an unavoidable hurdle for many enterprises. Although the certification process seems standardized, it actually hides many difficULties that cause numerous enterprises to stumble repeatedly. This article will deeply analyze the core difficulties of saa certification and answer common questions through an online Q&A format to help enterprises avoid detours.

Four Core Difficulties of SAA Certification

1. Complexity of Standard Adaptation

Australia's electrical safety standards (AS/NZS series) are significantly different from EU CE standards and are updated frequently. For example, lighting products must meet both the structural requirements of AS/NZS 60598 and the electromagnetic compatibility standards of AS/NZS CISPR 15. Some enterprises fail to track standard updates in a timely manner, leading to product unqualified due to minor parameter deviations (such as the temperature resistance level of insulating materials) during testing. They need to REDesign molds, resulting in a cost increase of more than 30%.

2. High Threshold of Testing Links

SAA certification covers more than 20 testing items, including electrical safety, mechanical strength, and flame retardant performance. Among them, the "abnormal operating condition test" is known as a "life-or-death barrier". For household electrical products, for example, it is necessary to simulate extreme scenarios such as voltage fluctuations and component short circuits to verify the product's self-protection capability. A certain electric kettle enterprise once failed the entire batch of product tests because the thermostat did not cut off power in time during the over-temperature test, delaying the launch time by nearly two months. In addition, Australia has strict requirements for component certification. For example, power cords must pass AS/NZS 3191 certification, and the use of non-compliant components will directly lead to the termination of testing.

3. Strictness of Factory Audits

High-risk products (such as medical equipment and high-power electrical appliances) need to pass factory audits. The audit focuses not only on the production process but also on supply chain management. Auditors will randomly select raw material batches to verify the consistency between supplier qualifications and test reports.

4. Uncontrollability of Certification Cycle

The conventional SAA certification cycle is about 8-12 weeks, but the rectification process after test failure may be extended to 6 months. If it involves standard updates, the completed test items may all become invalid. After the revision of AS/NZS 62133 in 2023, lithium battery products need to add a needle prick test. Many enterprises failed to predict in advance, resulting in a doubled certification cycle.

Analysis of Key Testing Requirements

Q: If the product has passed CE certification, can it be directly converted to SAA certification?

A: Direct conversion is not possible, but CE test reports can be used to exempt some items. For example, CE's LVD report can be used as a reference for electrical safety testing, but it is necessary to supplement Australia-specific tests (such as adaptability testing for the power grid voltage of 240V). It is recommended to choose a laboratory with both EU and Australian qualifications to avoid repeated testing. Please consult JJR Laboratory.

Q: How to quickly rectify after test failure?

A: First, require the laboratory to issue a detailed failure analysis report to clarify the root cause of the problem. If it is a structural defect (such as insufficient fire rating of the shell), it is necessary to replace materials that meet AS/NZS standards. If it is a circuit design problem, engineers with Australian certification experience can be hired to optimize the scheme. A certain coffee machine enterprise once exceeded the ground resistance standard and completed rectification and passed the re-test within 3 weeks by adding copper grounding terminals.

Q: Do small-batch trial-produced products require full SAA certification?

A: The Australian market strictly prohibits the sale of uncertified products. Even trial sales need to pass compliance testing. It is recommended to adopt a "phased certification" strategy: first complete full-item testing for core models and obtain certificates. Subsequent derivative models can apply for difference testing, which reduces costs while ensuring compliance.

Q: How to deal with the risks brought by standard updates?

A: You can sign a standard tracking service with the certification body to obtain update notices 6 months in advance. For products with a long life cycle (such as industrial motors), technical redundancy can be reserved during certification. For example, select insulating materials with a higher temperature resistance level to adapt to possible future standard upgrades.

Email:hello@jjrlab.com

Write your message here and send it to us

Is FCC Testing Required?

Is FCC Testing Required?

Where to Find FCC Test Reports

Where to Find FCC Test Reports

LFGB Compliance Testing for Plastic Food Contact M

LFGB Compliance Testing for Plastic Food Contact M

How to get LFGB Compliance Report for Food Grade P

How to get LFGB Compliance Report for Food Grade P

LFGB Certification Process for Kitchenware Product

LFGB Certification Process for Kitchenware Product

LFGB Test Requirements for Food Contact Materials

LFGB Test Requirements for Food Contact Materials

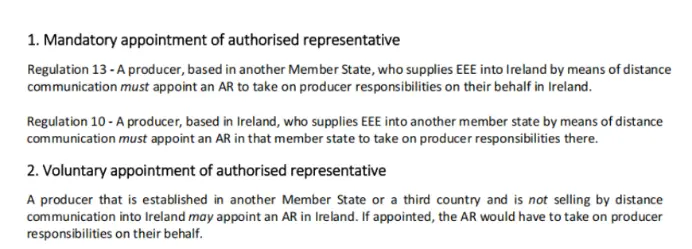

Irish Battery Act Requires an Authorised Represent

Irish Battery Act Requires an Authorised Represent

Swedish Battery Act Requires an Authorised Represe

Swedish Battery Act Requires an Authorised Represe

Leave us a message

24-hour online customer service at any time to respond, so that you worry!