What Are the Lithium Battery Safety Tests?

As an efficient energy supply, lithium batteries are widely used in various scenarios in today's modern society, such as electric vehicles, energy storage systems, consumer electronics, and other fields. Lithium battery safety testing is a critical step to ensure their safe and reliable operation. So what are the main test items? The following is a detailed introduction:

1. Overcharge Test

Designed to evaluate the safety performance of a battery under overcharging conditions. Under overcharge, a battery may experience issues such as temperature rise, gas generation, and capacity degradation. For example, the ul2054 standard requires that a battery must not catch fire, explode, or present other hazardous conditions under overcharge.

2. Overdischarge Test

Used to assess the safety performance of a battery under overdischarging conditions. Under overdischarge, a battery may encounter problems such as voltage drop, temperature rise, and capacity loss. For example, the iec 62133 standard requires that a battery must not catch fire, explode, or present other hazardous conditions under overdischarge.

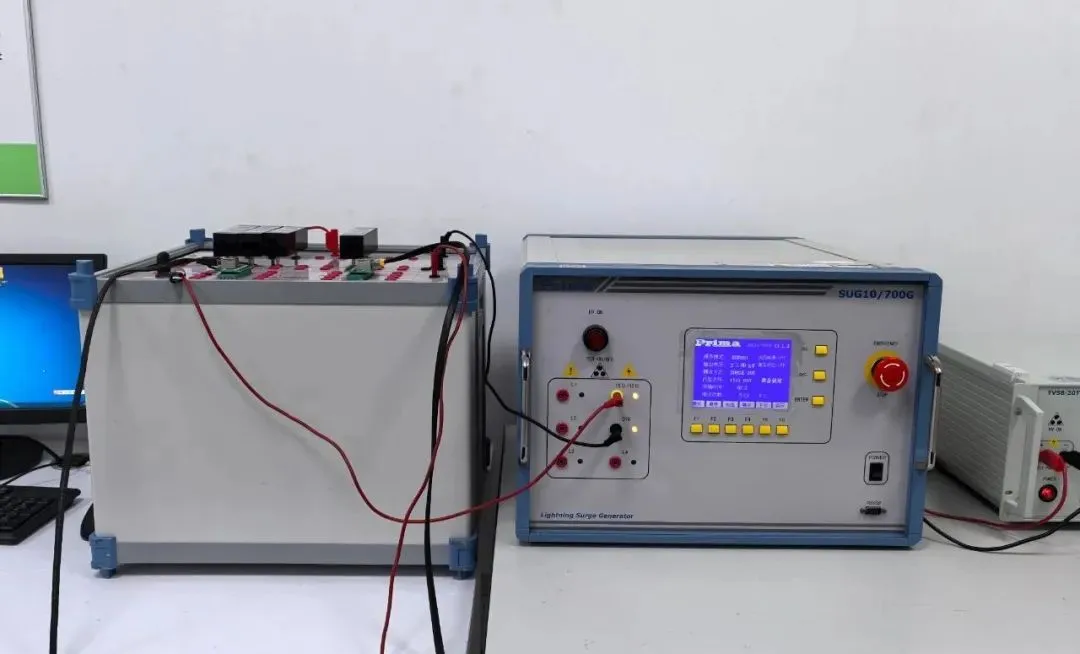

3. Short-Circuit Test

SimULates an accidental short circuit of the battery to evaluate its ability to withstand short-circuit current surges. The battery must not catch fire or explode during the short circuit, and the open-circuit voltage after the short circuit must not be lower than 90% of the nominal voltage.

4. Temperature Test

Used to evaluate the performance and safety of the battery under different temperature conditions. This includes testing the battery's capacity, voltage, cycle life, etc., under high and low temperature conditions. For example, the IEC 62133 standard requires that a battery must not catch fire, explode, or present other hazardous conditions under high and low temperature conditions.

5. Mechanical Shock Test

Simulates the safety of the battery when subjected to mechanical shocks (such as drops, collisions, etc.). During the test, parameters such as the degree of battery deformation and voltage changes are recorded, and observations are made for any occurrences of fire, explosion, or other phenomena.

6. Battery Pack Safety Tests

For battery packs, a series of system-level tests are also requiRED, including overcharge, overdischarge, short-circuit, temperature, and mechanical shock tests for the battery pack. For example, the IEC 62619 standard requires that a battery pack must not catch fire, explode, or present other hazardous conditions under various extreme conditions.

7. Battery Packaging and Transportation

Batteries must also meet specific safety requirements during packaging and transportation, including moisture resistance and shock resistance. For example, the UL2054 standard requires that batteries must not catch fire, explode, or present other hazardous conditions during packaging and transportation.

8. Thermal Abuse Test

Examines the safety of the battery under high-temperature conditions (typically 130°C). The battery must not rupture, catch fire, explode, or present other hazards.

9. Low-Pressure Test

Simulates the safety performance of the battery in low-pressure environments such as high altitudes.

10. Internal Short-Circuit Test

Used to verify whether the battery management system can effectively prevent internal short circuits, thereby ensuring the safe use of the battery.

11. Thermal Propagation Test

Used to evaluate whether thermal runaway of a single cell will spread to the entire battery system within the battery system.

12. Laser-Induced Thermal Runaway Propagation Test

Simulates the safety performance of the battery under extreme high temperatures, requiring that adjacent cells must not ignite.

13. Battery Management System (BMS) Function Test

Includes the evaluation of functions such as overcharge voltage protection, overcharge current protection, over-temperature protection, and thermal runaway propagation resistance, ensuring that the BMS operates effectively under abnormal battery conditions.

14. Vibration Test

Simulates the vibration environments that a battery may encounter during transportation or use, evaluating the battery's performance and durability under these conditions.

15. Nail Penetration Test

Evaluates the puncture resistance of the battery separator by penetrating the battery with a sharp object. This test is crucial for improving battery safety.

16. Drop Test

Simulates the scenario where a battery falls from a certain height onto a hard surface, evaluating the battery's structural integrity and safety. After the test, the battery is observed for damage, leakage, fire, or other phenomena.

17. Crush Test

Used to evaluate the safety of the battery when subjected to mechanical crushing, simulating the pressure the battery may experience during actual use. During the test, parameters such as the degree of battery deformation and voltage changes are recorded, and observations are made for any occurrences of fire, explosion, or other phenomena.

18. Battery Membrane Penetration Test

The battery membrane penetration test evaluates the puncture resistance of the battery separator. This test is crucial for improving battery safety.

19. Technical Specifications for Battery Module Test Systems

Specifies the terminology, technical requirements, test methods, etc., for lithium-ion battery module test systems, applicable to lithium-ion power battery packs and systems for electric vehicles.

20. Test Methods for Electrical Performance of Lithium-Ion Power Battery Packs and Systems for Electric Vehicles

Specifies the electrical performance test methods for lithium-ion power battery packs and systems for electric vehicles, including test procedures for high-power and high-energy applications.

21. Safety Requirements and Test Methods for Lithium-Ion Batteries for Power Energy Storage

Specifies the safety requirements and test methods for lithium-ion batteries for power energy storage, including the safety performance testing of battery cells and modules.

22. Safety Requirements for Moving Parts of Battery Systems

Includes anti-pinch and anti-misoperation features to better suit scenarios such as forklifts and AGVs.

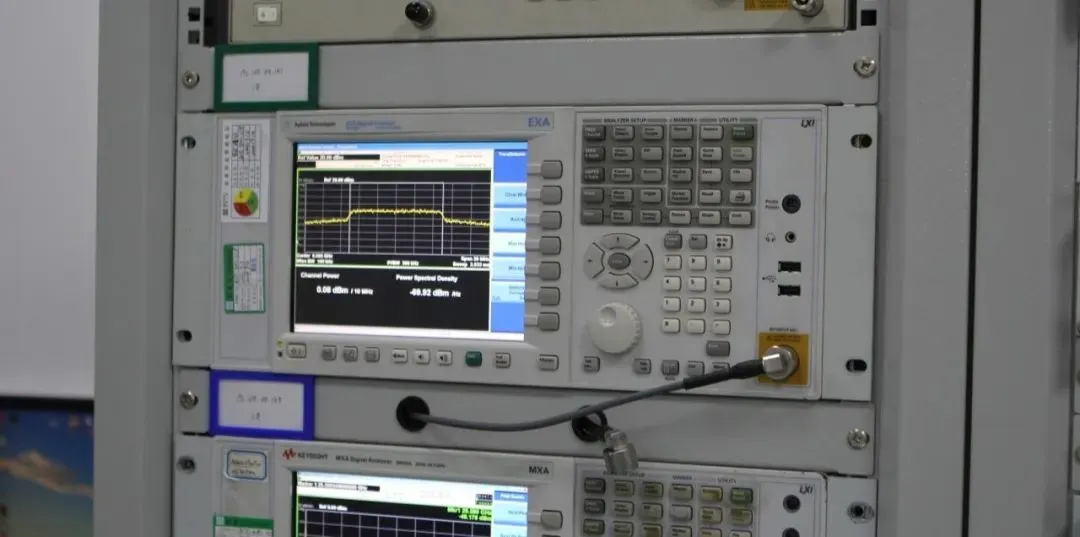

23. Electromagnetic Compatibility (EMC) Requirements

The battery system must comply with the iec 61000 standard to avoid functional abnormalities caused by electromagnetic interference.

24. Battery Systems Must Be Equipped with a "Key" or "Locking" Device

To prevent misoperation by non-professional personnel.

25. Reliable Insulation and Protection Measures Must Be Adopted for Live Parts Such as Battery Terminals and Wires

To avoid the risk of accidental electric shock.

Through the above corresponding safety tests, the safety and reliability of lithium batteries in various application scenarios can be ensured, providing standardized guidance for the safety assessment of lithium batteries.

Email:hello@jjrlab.com

Write your message here and send it to us

Global Certification Guide for Lithium Batteries

Global Certification Guide for Lithium Batteries

Compliance of Amazon 18650 Lithium Battery Product

Compliance of Amazon 18650 Lithium Battery Product

What is CE Certification and EU Authorized Represe

What is CE Certification and EU Authorized Represe

What Are the Lithium Battery Safety Tests?

What Are the Lithium Battery Safety Tests?

What is the EN 61326-2-3 Standard?

What is the EN 61326-2-3 Standard?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Retest the Device if the 5G Module Already Has

Why Retest the Device if the 5G Module Already Has

Overview of IEC 62087 Test Standard

Overview of IEC 62087 Test Standard

Leave us a message

24-hour online customer service at any time to respond, so that you worry!