What is the EN 61326-2-3 Standard?

Friends, today let's talk about the EN 61326-2-3 standard, which is a very important standard in the field of electrical equipment, and many products have to "deal" with it. Without further ado, let's get started!

What is the EN 61326-2-3 Standard?

EN 61326-2-3 is an electromagnetic compatibility (EMC) standard of the European Union for electrical equipment for measurement, control and laboratory use, specifically applicable to sensors with integrated or remote signal conditioning functions. It specifies the test configurations, operating conditions and performance requirements for such equipment, ensuring stable operation in complex electromagnetic environments without interfering with other devices.

Which Products Are Applicable to the EN 61326-2-3 Standard?

The EN 61326-2-3 standard applies to electrical equipment for measurement, control and laboratory use, especially those with integrated or remote signal conditioning functions. The following are some types of products applicable to this standard:

1. Various transmitters: such as pressure transmitters, differential pressure transmitters, temperature transmitters, level transmitters, flow transmitters, etc. These transmitters usually convert physical quantities into electrical signals and transmit the signals to control systems or display devices through signal conditioning functions.

2. Sensors and their systems: including various types of sensors, such as temperature sensors, humidity sensors, pressure sensors, displacement sensors, speed sensors, acceleration sensors, etc., as well as measurement systems composed of these sensors. If these sensors are equipped with integrated or remote signal conditioning functions to convert sensor signals into usable electrical signal outputs, they are applicable to this standard.

3. Analytical instruments: for example, spectrometers and chromatographs for cheMICal analysis, as well as densitometers, viscometers and other analytical instruments for physical property measurement. These instruments usually contain signal conditioning circuits to process the signals acquiRED by the sensors and provide accurate measurement resULts.

4. Data acquisition equipment: data loggers, data recorders and other equipment used to collect various physical quantities or electrical signals. They may have signal conditioning functions to adapt to different types of sensor inputs and convert data into digital signals for storage and transmission.

5. Industrial control equipment: such as programmable logic controllers (PLC), input and output modules in distributed control systems (DCS), fieldbus equipment, etc. These equipment are used to control and monitor process variables in industrial automation systems, and usually need to process signals from various sensors, as well as perform signal conditioning and transmission.

6. Laboratory instruments: for example, electronic balances, pH meters, conductivity meters, oscilloscopes, signal generators and other instruments used in laboratories. These instruments are used for measurement and experiments in laboratories, and usually have signal conditioning and processing functions to provide accurate measurement results and output signals.

What Items Are Tested in the EN 61326-2-3 Standard?

Electromagnetic Emission Tests

① Conducted emission

② Radiated emission

Electromagnetic Immunity Tests

① Electrostatic discharge immunity

② Radiated radio-frequency electromagnetic field immunity

③ Electrical fast transient/burst immunity

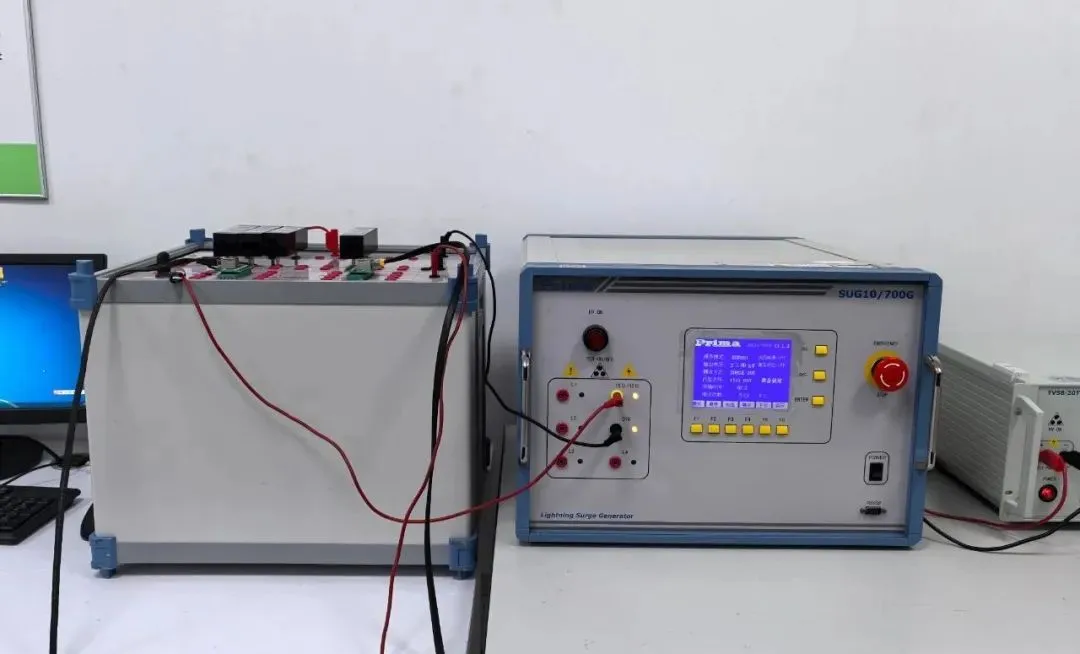

④ Surge immunity

⑤ Conducted immunity

What Should Be Noted for CE certification Using This Standard?

1. Accurate standard selection: Be sure to confirm that the product is applicable to the EN 61326-2-3 standard. Do not choose the wrong one, otherwise the certification will be in vain.

2. Product consistency: The test products during the certification process must be consistent with the actually produced products. The product cannot be one way during testing and another way when produced.

3. Certification body selection: Choose a qualified and reputable certification body. If you choose an unreliable one, the certification results may not be recognized, and all efforts will be for nothing.

4. Timely attention to standard updates: The EN 61326-2-3 standard may be updated with the development of technology and the needs of practical applications. Manufacturers must keep an eye on changes to the standard to ensure that products always comply with the latest requirements, otherwise the certification obtained with great effort may become invalid.

5. Performance degradation statement: If the equipment allows performance degradation under interference, it must be clearly marked in the instruction manual.

6. Laboratory qualification: Select a third-party laboratory recognized by the European Union to avoid invalid tests.

7. Document integrity: Technical documents must include full-process records of design, testing and risk analysis.

8. Actual product testing: Testing must be conducted on mass-produced models, not prototype samples.

Well, that's all for today's sharing about the EN 61326-2-3 standard. I hope you have a clearer understanding of this standard. Share this article with more friends in need, it may help them. If you have any further questions, please contact me.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the EN 61326-2-3 Standard?

What is the EN 61326-2-3 Standard?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Retest the Device if the 5G Module Already Has

Why Retest the Device if the 5G Module Already Has

Overview of IEC 62087 Test Standard

Overview of IEC 62087 Test Standard

CISPR 25 Test Standard Compliance Guide

CISPR 25 Test Standard Compliance Guide

IEC/UL/CSA 62368-1 Electrical Distance Testing

IEC/UL/CSA 62368-1 Electrical Distance Testing

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Leave us a message

24-hour online customer service at any time to respond, so that you worry!