Environmental Reliability Testing Laboratory

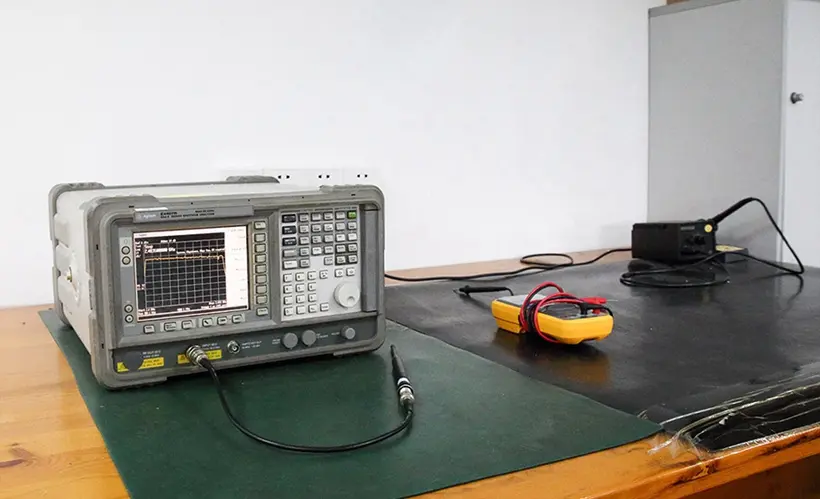

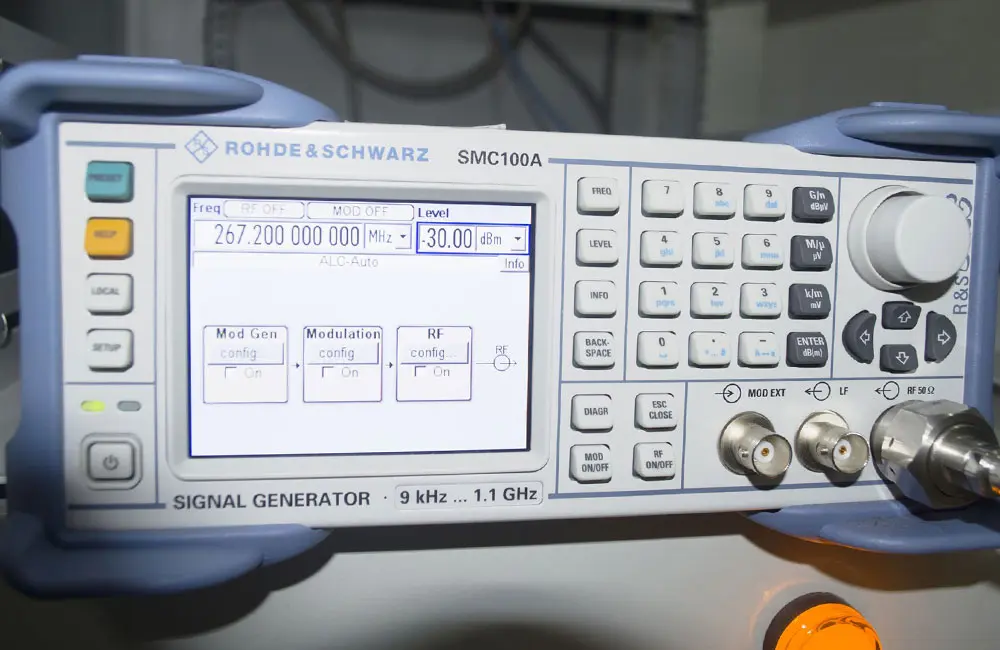

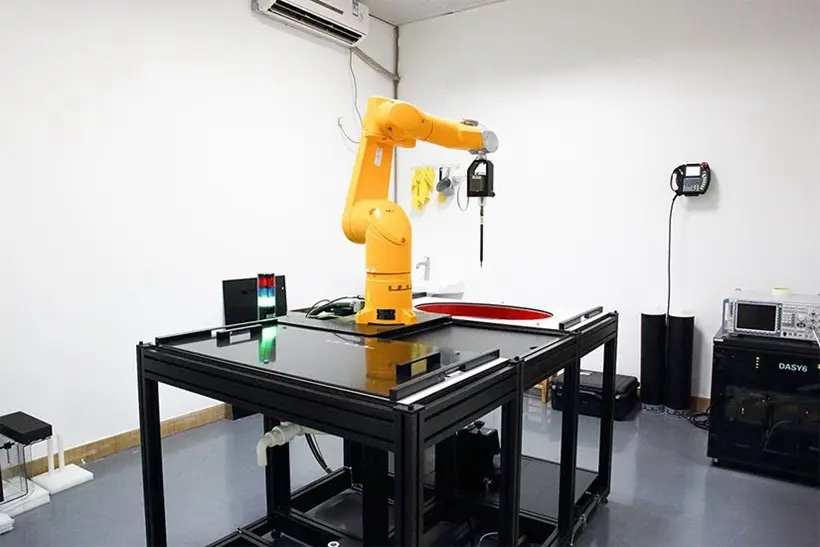

China JJR Laboratory offers product environmental reliability testing services. The laboratory is located in China and holds qualifications such as IEC 17025, CMA, and CNAS certificates.

Reliability Testing includes:

- Environmental reliability

- Salt spray testing

- Weather resistance

- Aging performance testing

- Fatigue testing

- UV testing

- Corrosion testing

High Temperature Testing

High-temperature testing simULates the high-temperature conditions during storage, assembly, and usage of products, aiming to determine the adaptability and durability of military and civilian equipment and components under normal temperature conditions.

Low Temperature Testing

The purpose of low-temperature testing is to examine whether specimens can be stoRED and operated in long-term low-temperature environments, confirming the adaptability and durability of materials under low-temperature conditions.

Thermal Shock Testing

Thermal shock testing exposes test samples to continuous alternating environments of high and low temperatures to assess the product's adaptability to rapid changes in ambient temperature.

Rapid Temperature Change Testing

Rapid temperature change testing is used to determine the adaptability of products to rapid temperature changes in climatic environments during storage, transportation, and usage.

Altitude Temperature Testing

Altitude temperature testing is used to test and determine the parameters and performance of electrical, electronic, and other products and materials after temperature environmental changes such as high temperature, low temperature, alternating humidity, or constant testing.

Temperature-Humidity Cycling Testing

Temperature-humidity cycling testing exposes samples to alternating test environments of set temperature and humidity to evaluate changes in functional characteristics after temperature and humidity environmental cycles or storage.

Constant Temperature-Humidity Testing

Constant temperature-humidity testing simulates specific temperature and humidity tests on test items under high temperature, low temperature, and humid environments.

Combined Environmental Testing

Combined environmental testing applies simultaneous stresses of temperature + humidity + vibration to provide a more realistic and practical reflection of product performance under field use.

Vibration Testing

Vibration testing is used to assess the effects of various vibration environments encountered during storage, transportation, installation, and usage of products.

Mechanical Shock Testing

Mechanical shock testing simulates a series of shocks that products encounter in working environments to evaluate whether the product functions normally and whether there are performance failures.

Mechanical Impact Testing

Impact testing simulates mechanical impact environments encountered during use, transportation, and unloading processes to verify product adaptability and the integrity of its structure.

Salt Spray Testing

Salt spray testing is used to assess the corrosion resistance of products or metal materials through environmental tests, divided into natural environmental exposure tests and artificial accelerated simulation salt spray environmental tests.

Xenon Lamp Aging

Xenon lamp aging testing simulates the damage of materials by sunlight and moisture in the natural environment to detect aging conditions when exposed to sunlight.

UV Aging

UV aging testing evaluates changes in performance after UV aging by simulating sunlight UV environments.

Waterproof Testing

Waterproof testing is suitable for electrical and electronic products that may encounter water splashes, evaluating product performance under these conditions.

Dustproof Testing

Dustproof testing is used to detect the protective performance of products in dusty environments to determine their performance in such environments during use, storage, and transportation.

Scratch Testing

Scratch testing is used to evaluate the bonding strength between surface films and substrate materials by creating scratches to assess bonding strength.

Friction Resistance Testing

Friction resistance testing evaluates the wear resistance of sample surfaces by applying loads with a friction head to assess sample wear resistance.

Cross-Hatch Testing

Cross-hatch testing is used to assess the adhesion degree of coatings to substrates by evaluating the integrity of coatings through cross-hatch methods.

Drop Ball Impact Testing

Drop ball impact testing evaluates the energy required for bonded specimens to crack under the impact of dropped balls from different heights.

MICro Drop Test

Micro drop testing is suitable for drop testing of small consumer electronic products to evaluate their drop performance.

HAST Aging Testing

HAST aging testing is used for accelerated life testing to reduce the testing time for product or system life tests.

Toxicology Experiments

Toxicology experiments evaluate the toxicity and potential hazards of chemicals by conducting poisoning tests on experimental animals to provide data for product safety assessment.