ASTM F963 Heavy Metal Toys

The ASTM F963 toy testing is designed to help manufacturers and relevant practitioners ensure their products comply with U.S. safety standards.

Identify Applicable Standards and Scope

① Standard Version:Confirm the latest version of ASTM F963 (e.g., 2023 edition) and cross-check mandatory requirements from the U.S. CPSC.

② Product Classification:Determine testing focus based on the toy’s intended age group (e.g., 0–3 years, 3–6 years). For example, small parts testing is mandatory for toys intended for children under 3 years.

Material Review and Sample Preparation

① Material List:Collect safety data sheets (SDS) for all materials (plastics, coatings, textiles, etc.) to ensure no prohibited substances are present.

② Sample Quantity:Prepare sufficient samples (typically 35 units) for different testing items.

Physical and Mechanical Performance testing

1. Small Parts Test (for toys under 3 years):

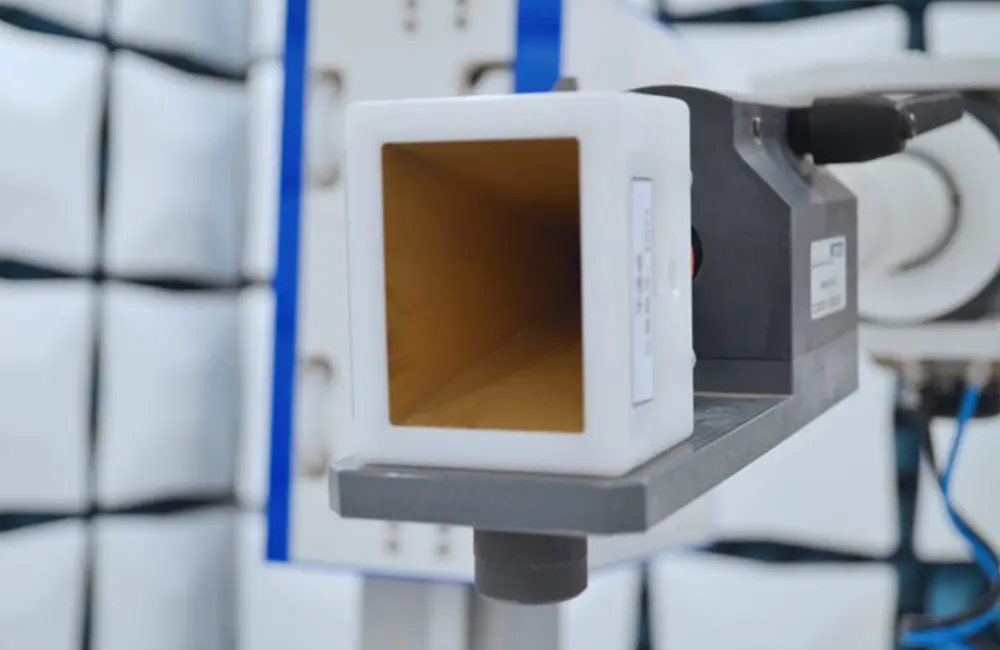

① Use a “small parts cylinder” (diameter 31.7 mm) to check if components can be swallowed.

② Conduct a pULl test (90 N held for 10 seconds) and drop test (drop from 85 cm height five times) to ensure no small parts detach.

2. Sharp Edges and Points:

① Sharp edges:Assess using a RED-line gauge (≤0.5 mm radius considered sharp) or tactile evaluation.

② Sharp points:Use a tip tester (apply 4.5 N force; if it pierces a film, it fails).

3. Other Mechanical Hazards:

① Moving gaps:Check for finger pinching risks (gaps of 5–12 mm must meet requirements).

② Projectile hazards:Test projectile kinetic energy (≤0.08 J) and blunt any sharp tips.

Flammability Testing

Burn Rate:Conduct horizontal/vertical burn tests on hair, textiles, and other materials (burn rate must be ≤30 mm/s).

CheMICal Toxicity Testing

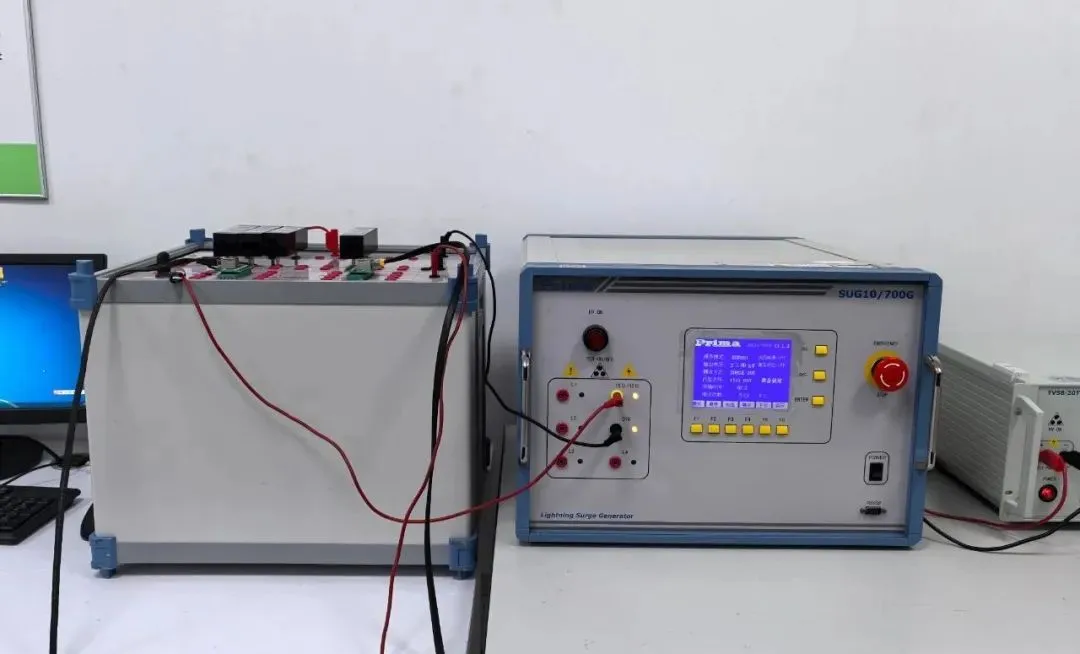

1. Heavy Metal Migration (per CPSC method or en 71-3):

Lead (≤100 ppm), Cadmium (≤75 ppm), Mercury, and 8 other heavy metals.

2. Phthalates (per CPSC requirements):

DEHP, DBP, and 6 other plasticizers ≤0.1%.

Total Lead Content (surface coatings):≤90 ppm (per U.S. cpsia requirements).

Labeling and Warning Checks

① Age Warnings:Indicate “Not for children under 3 years” if small parts are present.

② Manufacturer Information:Clearly display origin, company name, and address.

③ Compliance mark:e.g., “ASTM F963 Compliant.”

Laboratory Testing and Reporting

① Select Laboratory:Ensure the lab is CPSC-recognized or ISO 17025 certified.

② Testing Cycle:Typically 7–10 business days (may be longer for complex items).

③ Test Report:Obtain a detailed report listing pass/fail items.

Email:hello@jjrlab.com

Write your message here and send it to us

What is the EN 61326-2-3 Standard?

What is the EN 61326-2-3 Standard?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Do Smart Sockets Need IEC 60884 Certification?

Why Retest the Device if the 5G Module Already Has

Why Retest the Device if the 5G Module Already Has

Overview of IEC 62087 Test Standard

Overview of IEC 62087 Test Standard

CISPR 25 Test Standard Compliance Guide

CISPR 25 Test Standard Compliance Guide

IEC/UL/CSA 62368-1 Electrical Distance Testing

IEC/UL/CSA 62368-1 Electrical Distance Testing

Canada Wireless Device IC Certification RSS-210 Te

Canada Wireless Device IC Certification RSS-210 Te

FCC Part 15.231 for Wireless Remote Controls and S

FCC Part 15.231 for Wireless Remote Controls and S

Leave us a message

24-hour online customer service at any time to respond, so that you worry!