How to Prepare for Wireless Product Certification Testing?

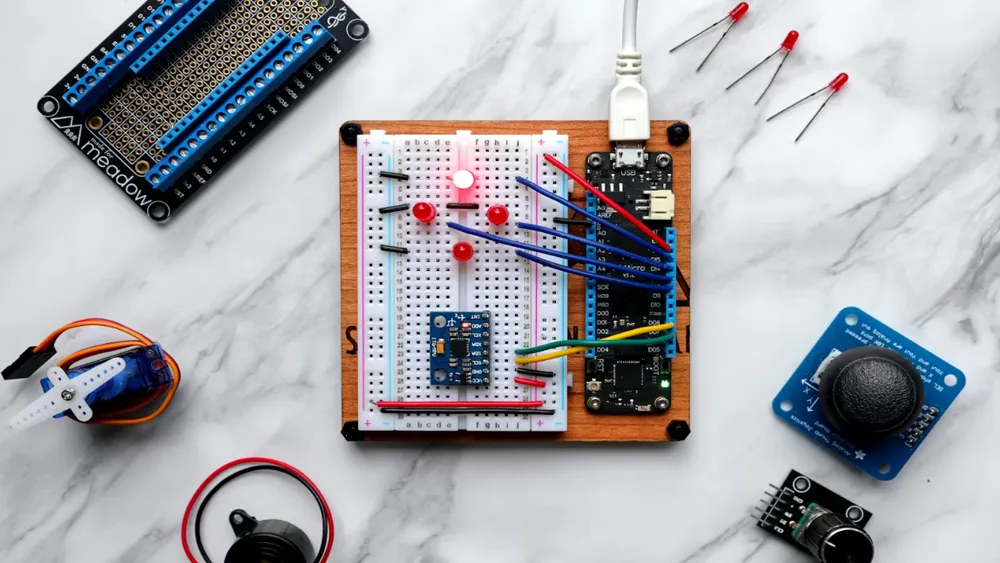

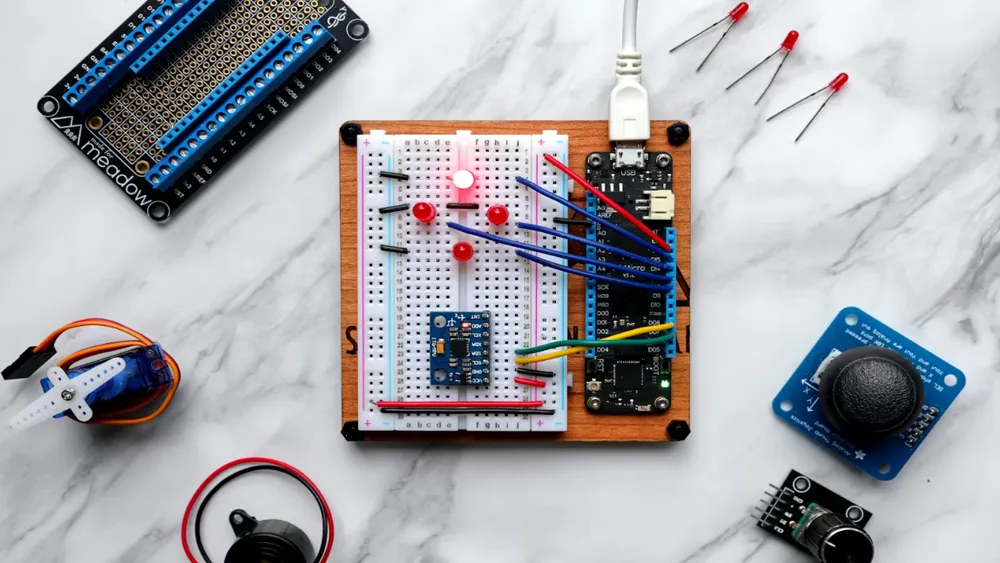

Anyone in the wireless product industry knows that products must pass certification testing before hitting the market. However, if you fail to prepare a basic fixed-frequency prototype before sending it to the lab, you will not only waste time but also risk incurring high re-testing costs!

This guide systematically explains the preparation work for conducted and radiated fixed-frequency prototypes, covering hardware processing and software control, and provides a step-by-step tutorial on correctly preparing prototypes for certification testing.

I. Two Types of Prototypes: Conducted vs. Radiated – What’s the Difference?

1. Conducted Fixed-Frequency Prototype

Core Requirements:

① Antenna must be cut off

② SMA coaxial cable must be soldeRED

③ Fixed-frequency software must be running

Purpose: Test the performance of the RF chip itself and eliminate antenna variables. This is the "basic skill" for verifying hardware design.

2. Radiated Fixed-Frequency Prototype

Core Requirements:

① Antenna must remain intact

② Fixed-frequency software must be running

Purpose: SimULate real-world usage scenarios and test the performance of the complete device via antenna radiation.

In short: Conducted testing evaluates the "chip", while radiated testing evaluates the "device". Both require fixed-frequency operation, and the key difference lies in whether the antenna is intact.

Four Fixed-Frequency Control Methods – There’s One for Everyone

1. Direct Connection Method (Beginner-Friendly)

Operation: Directly connect the prototype to a computer using a USB cable

Applicable Scenarios:

① The prototype has a built-in USB debugging port

② Supports plug-and-play communication

③ No disassembly required; simple operation

Precautions:

① Ensure the computer can recognize the COM port

② Install the correct driver software

2. Serial Port Board Adapter Method (Universal Solution)

Operation: Lead out test wires → Connect to serial port board → Connect to computer

Four Wires to Be Led Out:

① TX (Transmit Data Line)

② RX (Receive Data Line)

③ GND (Ground Line)

④ VCC (Power Line)

Two Leading-Out Methods:

① Method A: Lead out from an external interface

② Method B: Lead out from internal test points (more commonly used)

3. Signaling Mode Method (Exclusive for Cellular Products)

Applicable Products: 4G/5G modules, cellular IoT devices

Working Principle:

The prototype enters signaling mode → Connect to the lab’s base station simulator → The base station fully controls the prototype’s transmission

Advantages: Standardized testing with high efficiency; a mandatory method for operator warehouse entry testing.

4. Customized Solution (Advanced Method)

Any method works as long as it achieves one goal: enabling the prototype to transmit stably at a fixed frequency!

Practical Operation Guide (with Detailed Steps)

Step 1: Hardware Preparation

Conducted Prototype Operation Process:

1. Locate the antenna feed point

2. Carefully cut off the antenna with a hot air gun

3. Solder a high-quality SMA coaxial cable

4. Use a multimeter to check if the connection is secure

Tool List:

① Hot air gun/soldering iron

② SMA connector

③ Coaxial cable (RG178 recommended)

④ Multimeter

⑤ Magnifying glass

Step 2: Software Configuration

Firmware Burning Key Points:

A. Use dedicated fixed-frequency test firmware

B. Confirm the firmware supports the following functions:

① Lock to a specific channel

② Set fixed power

③ Continuous transmission mode

④ Debugging information output

Computer-Side Configuration:

Python |

Step 3: Connection Verification

Verification Checklist:

① The computer recognizes the COM port

② The fixed-frequency software can connect to the prototype

③ Frequency and power can be set

④ A stable signal is visible on the spectrum analyzer

Troubleshooting Guide: Common Problems and Solutions

Problem 1: Unstable Connection

Possible Causes:

① Poor solder joints

② Low-quality cables

③ Incompatible drivers

Solutions:

① Resolder the connection points

② Replace with high-quality cables

③ Install official drivers

Problem 2: Fixed-Frequency Failure

Possible Causes:

① Incorrect firmware version

② Invalid control commands

③ Hardware incompatibility

Solutions:

① Check the chip datasheet

② Contact the original manufacturer for the correct SDK

③ Inspect the hardware circuit

Problem 3: Abnormal Test Data

Possible Causes:

① Environmental interference

② Instrument calibration issues

③ Abnormal prototype status

Solutions:

① Test in a shielded environment

② Calibrate instruments regularly

③ Prepare multiple prototypes for comparison

Pre-Testing Self-Inspection Checklist Before Sending to the Lab

Before incurring high lab testing fees, be sure to complete the following self-inspections:

Hardware Inspection:

① SMA connector is soldered securely

② Antenna processing meets requirements

③ All screws are tightened

④ Housing is intact with no damage

Software Inspection:

① Fixed-frequency function works normally

② Power is adjustable across all channels

③ Debugging information can be output

④ No abnormal restart issues

Document Preparation:

① Prototype configuration instructions

② Fixed-frequency operation guide

③ Contact information

④ Expected test items

Experience Sharing: Tips to Improve First-Pass Rate

Tip 1: Conduct Pre-Testing in Advance

Perform simple pre-tests during the R&D phase to avoid most basic errors.

Essential Pre-Test Items:

① Basic RF performance

② Key frequency power

③ Basic function verification

Tip 2: Prepare Multiple Prototypes

It is recommended to prepare at least:

① 3 conducted prototypes

② 3 radiated prototypes

This prevents test interruptions caused by single-prototype failures.

Tip 3: Communicate with the Lab in Advance

Before sending prototypes:

① Confirm the lab’s specific requirements

② Obtain the lab’s prototype preparation guidelines

③ Understand the testing process and timeline

Summary: Core Points for Fixed-Frequency Prototype Preparation

Remember these three points, and prototype preparation will no longer be a hassle:

1. Clarify requirements: Distinguish between conducted and radiated testing, and handle hardware correctly

2. Choose the right method: Select an appropriate fixed-frequency control method based on product characteristics

3. Conduct thorough verification: Complete comprehensive self-inspection and pre-testing before sending to the lab

Email:hello@jjrlab.com

Write your message here and send it to us

How to Prepare for Wireless Product Certification

How to Prepare for Wireless Product Certification

What Compliance is Required for Exporting Robot Va

What Compliance is Required for Exporting Robot Va

FCC Requires Equipment Exporters to Provide "

FCC Requires Equipment Exporters to Provide "

What Tests Are Required for CE LVD, EMC and RED Di

What Tests Are Required for CE LVD, EMC and RED Di

What are the UL certification service providers?

What are the UL certification service providers?

What is CE certification equivalent in USA?

What is CE certification equivalent in USA?

2026 Japan METI Filing & Local Representative

2026 Japan METI Filing & Local Representative

How to Obtain a CE Mark?

How to Obtain a CE Mark?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!