How to Conduct REACH Testing for Exporting to the EU

In global trade, the European Union (EU) market is renowned for its stringent product standards and regULatory requirements. For many companies aiming to enter the EU market, reach testing is an unavoidable checkpoint. So, what exactly is REACH testing, and how can companies successfully pass it? Today, we will take a deep dive into REACH testing.

What is reach regulation?

REACH stands for Registration, Evaluation, Authorization, and Restriction of CheMICals. It is a major EU regulation that enforces preventive management of all chemicals entering its market, aiming to protect human health and environmental safety while promoting the competitiveness of the EU chemical industry. The regulation officially came into effect on June 1, 2007, imposing strict requirements on chemicals and downstream products produced, imported, or sold within the EU.

Why Your Product Must Pass REACH Testing

Legal Requirement

The EU REACH regulation controls over 250 Substances of Very High Concern (SVHCs)(as of June 2025), covering nearly every industry including electronics, toys, textiles, and plastics. Products containing these substances above certain limits must comply with the regulations.

Severe Consequences of Non-Compliance

1. Detention or Recall:EU customs strictly inspect SVHC content. Products exceeding 0.1% SVHC without notification risk being detained or recalled.

2. Heavy Fines:Violations can result in fines up to €2 millionper incident, imposing a serious financial burden on companies.

3. Brand Reputation Damage:In an era focused on environmental protection and product safety, failure in reach compliance can severely damage a company's brand reputation, affecting future market expansion and partnerships.

Products CoveRED by REACH Testing

- Electronics:Cables, casings, electronic components, etc. These may contain flame retardants, heavy metals, and other chemicals that must meet REACH requirements to enter the EU.

- Children’s Products:Coatings, plastic parts, toys, etc. Safety is critical as these products directly contact children. REACH imposes stricter limits on harmful substances in children’s products.

- Packaging Materials:Inks, adhesives, paper, plastic packaging, etc. Packaging may indirectly contact products during transport and sales, so chemical migration must be tested under REACH.

- Metal Alloys:Coatings, solders, metal products, etc. Chemical additives used to improve performance must comply with REACH requirements.

Core Content and Process of REACH Testing

(1) Three Major Test Modules

1. SVHC Screening:Detects whether the product contains any of the 250 SVHCs (e.g., phthalates, polycyclic aromatic hydrocarbons). If levels exceed limits, the product fails compliance.

2. Annex XVII Restricted Substances:Verifies limits for 79 substancesincluding lead, cadmium, and nickel release. Companies must ensure these levels meet standards.

3. SCIP Notification:If SVHC content exceeds 0.1%, the supplier must report the SVHC information to the EU SCIP database to improve supply chain transparency.

(2) Testing Process

1. Material List Analysis:Experts analyze the product’s material list to identify potential risk materials and determine initial test items.

2. Sampling:Representative samples are taken from different parts and materials to ensure accurate overall test results.

3. Chemical Testing (GC-MS / ICP-OES):Advanced instruments like Gas Chromatography-Mass Spectrometry (GC-MS)and Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)analyze chemical composition and detect harmful substance levels.

4. Report & Optimization Suggestions:After testing, a professional report is provided with interpretation and suggestions for product improvement to meet regulatory requirements.

5. Compliance certificate (Bilingual):If the product passes, a bilingual (Chinese/English) certificate is issued, proving compliance and allowing smooth entry into the EU market.

How to Choose a Reliable REACH Testing Lab

1. Beware of Low-Cost Traps:Price is a factor, but extremely low-cost labs may cut corners, producing inaccurate results and causing greater losses.

2. Verify Qualifications:

- EU Authorized Labs:Officially recognized for testing capability and technical level.

- CMA Certification:Labs with Chinese Metrology Accreditation (CMA) reports are widely accepted internationally.

3. Data Traceability:Reliable labs provide raw spectra and testing method details, ensuring authenticity and accuracy of test results.

Three Applications of reach test reports

1. Export Customs Clearance:EU customs require REACH test reports to verify imported goods. Only compliant reports ensure smooth entry into the EU.

2. Brand Access:Major international brands (e.g., Apple, Samsung) mandate REACH compliance from suppliers to maintain environmental standards and brand image.

3. Green Certification:REACH reports support applications for Eco-labels, Blue Angel, and other environmental certifications, enhancing product competitiveness and meeting consumer demand for eco-friendly products.

Email:hello@jjrlab.com

Write your message here and send it to us

What is Bisphenol A (BPA) Testing?

What is Bisphenol A (BPA) Testing?

LED Display Export to the EU CE-EMC + RoHS Directi

LED Display Export to the EU CE-EMC + RoHS Directi

Children's Sleepwear Flammability 16 CFR 1615 / 16

Children's Sleepwear Flammability 16 CFR 1615 / 16

Speaker SAA & RCM Compliance AS/NZS 62368.1:20

Speaker SAA & RCM Compliance AS/NZS 62368.1:20

What is IEC 62052 for Electrical Energy Measuring

What is IEC 62052 for Electrical Energy Measuring

Australia LoRa Band 915-928 MHz RCM Compliance

Australia LoRa Band 915-928 MHz RCM Compliance

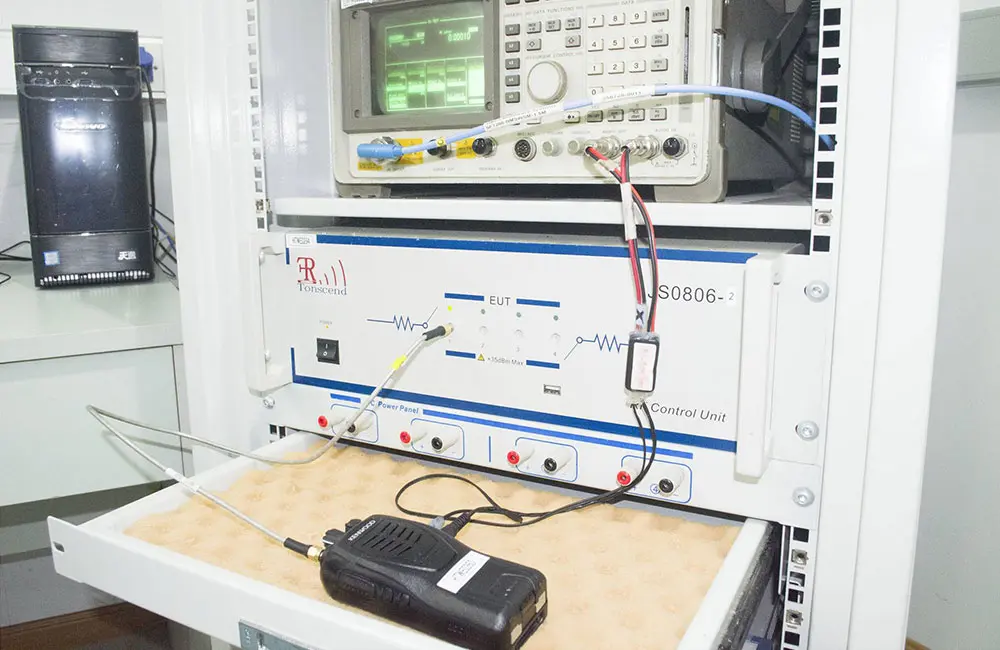

What Are the Compliance Certifications for VHF Pro

What Are the Compliance Certifications for VHF Pro

Which Products Require WERCS Registration?

Which Products Require WERCS Registration?

Leave us a message

24-hour online customer service at any time to respond, so that you worry!